Page 18 - MACHINE TOOLS WORLD - September 2021

P. 18

BUSINESS NEWS

WIDIA Introduces M1600 Face Milling Platform

Suitable for Variety of Machine Conditions & Set Ups

WIDIA™ announced the release of the performs best in dry applications but

M1600 face mill for roughing to semi- can also be used in wet conditions. The

finishing operations in steel, stainless universal WU20PM grade can be used for

steel, cast iron and nodular iron materials. the machining of steel, stainless steel and

With 16-cutting edges and a smart insert high-temperature alloys in both dry and

design, the M1600 performs in various wet applications.

machining conditions including low-power The ‘smart’ insert design features a

machines, unstable, non-rigid set ups, long seating surface below the cutting edge

overhangs, weak machines or weak fixture that promotes smooth chip flow and re-

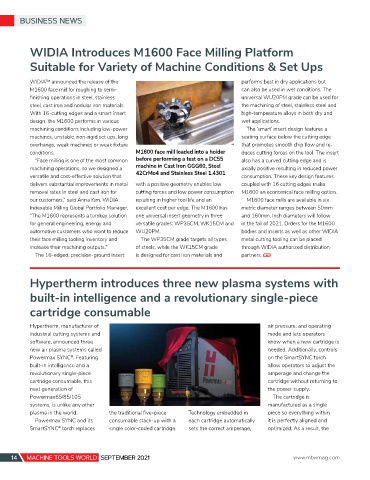

conditions. M1600 face mill loaded into a holder duces cutting forces on the tool. The insert

“Face milling is one of the most common before performing a test on a DC55 also has a curved cutting edge and is

machining operations, so we designed a machine in Cast Iron GGG60, Steel axially positive resulting in reduced power

versatile and cost-effective solution that 42CrMo4 and Stainless Steel 1.4301 consumption. These key design features

delivers substantial improvements in metal with a positive geometry enables low coupled with 16 cutting edges make

removal rates in steel and cast iron for cutting forces and low power consumption M1600 an economical face milling option.

our customers,” said Anna Kim, WIDIA resulting in higher tool life and an M1600 face mills are available in six

Indexable Milling Global Portfolio Manager. excellent cost per edge. The M1600 has metric diameter ranges between 50mm

“The M1600 represents a turnkey solution one universal insert geometry in three and 160mm. Inch diameters will follow

for general engineering, energy and versatile grades: WP35CM, WK15CM and in the fall of 2021. Orders for the M1600

automotive customers who want to reduce WU20PM. bodies and inserts as well as other WIDIA

their face milling tooling inventory and The WP35CM grade targets all types metal cutting tooling can be placed

increase their machining outputs.” of steels, while the WK15CM grade through WIDIA authorized distribution

The 16-edged, precision-ground insert is designed for cast iron materials and partners.

Hypertherm introduces three new plasma systems with

built-in intelligence and a revolutionary single-piece

cartridge consumable

Hypertherm, manufacturer of air pressure, and operating

industrial cutting systems and mode and lets operators

software, announced three know when a new cartridge is

new air plasma systems called needed. Additionally, controls

Powermax SYNC . Featuring on the SmartSYNC torch

®

built-in intelligence and a allow operators to adjust the

revolutionary single-piece amperage and change the

cartridge consumable, this cartridge without returning to

next generation of the power supply.

Powermax65/85/105 The cartridge is

systems, is unlike any other manufactured as a single

plasma in the world. the traditional five-piece Technology embedded in piece so everything within

Powermax SYNC and its consumable stack-up with a each cartridge automatically it is perfectly aligned and

SmartSYNC torch replaces single color-coded cartridge. sets the correct amperage, optimized. As a result, the

®

14 MACHINE TOOLS WORLD SEPTEMBER 2021 www.mtwmag.com