Page 61 - MACHINE TOOLS WORLD - September 2021

P. 61

TECH INNOVATION

grinding using Pinch/Peel, Roughing,

or only a finishing pass on an individual

step segment if required.

The operator can also choose the

amount of stock per segment to be

removed. The stock removal is applied

radially (on the diameter) or axially for

features such as square shoulders.

The operator is guided through a

step-by-step process to create the

blank geometry and stock removal per

segment. Programming a blank from

scratch using BlankX only takes a few

minutes, drastically reducing setup time.

When applying different stock removal

per segment, the blank profile appears

on the operations page. The blank

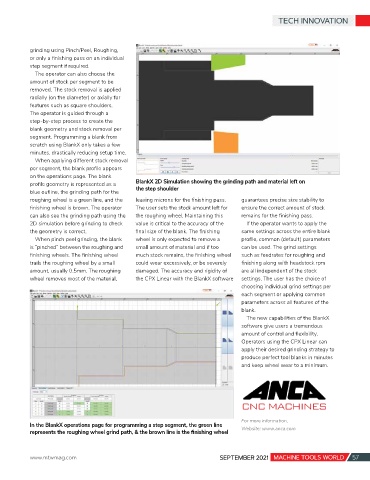

profile geometry is represented as a BlankX 2D Simulation showing the grinding path and material left on

blue outline, the grinding path for the the step shoulder

roughing wheel is a green line, and the leaving microns for the finishing pass. guarantees precise size stability to

finishing wheel is brown. The operator The user sets the stock amount left for ensure the correct amount of stock

can also see the grinding path using the the roughing wheel. Maintaining this remains for the finishing pass.

2D simulation before grinding to check value is critical to the accuracy of the If the operator wants to apply the

the geometry is correct. final size of the blank. The finishing same settings across the entire blank

When pinch peel grinding, the blank wheel is only expected to remove a profile, common (default) parameters

is “pinched” between the roughing and small amount of material and if too can be used. The grind settings

finishing wheels. The finishing wheel much stock remains, the finishing wheel such as feedrates for roughing and

trails the roughing wheel by a small could wear excessively, or be severely finishing along with headstock rpm

amount, usually 0.5mm. The roughing damaged. The accuracy and rigidity of are all independent of the stock

wheel removes most of the material, the CPX Linear with the BlankX software settings. The user has the choice of

choosing individual grind settings per

each segment or applying common

parameters across all features of the

blank.

The new capabilities of the BlankX

software give users a tremendous

amount of control and flexibility.

Operators using the CPX Linear can

apply their desired grinding strategy to

produce perfect tool blanks in minutes

and keep wheel wear to a minimum.

For more information,

In the BlankX operations page for programming a step segment, the green line Website: www.anca.com

represents the roughing wheel grind path, & the brown line is the finishing wheel

www.mtwmag.com SEPTEMBER 2021 MACHINE TOOLS WORLD 57