Page 18 - MACHINE TOOLS WORLD MARCH 2022 Digital Magazine

P. 18

BUSINESS NEWS

sets the correct pressure and minimizes minimize downtime. Vandergon, Waterjet Product Marketing

fluctuations to improve component Manager. “It builds upon everything

life, while offering the most efficient Combined with an optional Tilt-A-JET OMAX has learned during the past three

waterjet pump technology in the taper compensation head, the new decades to deliver the most capable and

market. OptiMAX is the most accurate system efficient waterjet cutting system available

• IntelliTRAX drive system with advanced on the market. In addition, it provides today, so our customers are able to easily

motion control for further increased advanced optional usability features achieve optimal cutting outcomes.”

system robustness and reliability. such as water level control, under bridge Like every OMAX system, all OptiMAX

Requires virtually no maintenance lighting, and a machine status indicator, products include comprehensive after-

compared to more conventional along with fast, accurate, and efficient sales service, unlimited free training, and

ball screw and rack and pinon drive cutting. software upgrades, as well as a host of

systems. “The OptiMAX represents the pinnacle efficiency centered resources to maximize

• New garnet delivery system to further in abrasive waterjet cutting,” said Arion uptime and keep customers cutting.

Kennametal Introduces Lightest Weight Version of Electric

Vehicle Tooling Solution Saving Set-up and Machining Time

surface qualities.

The newly redesigned tool recently

won MM MaschinenMarkt’s Best of

Industry Award in the Production and

Manufacturing category based on votes by

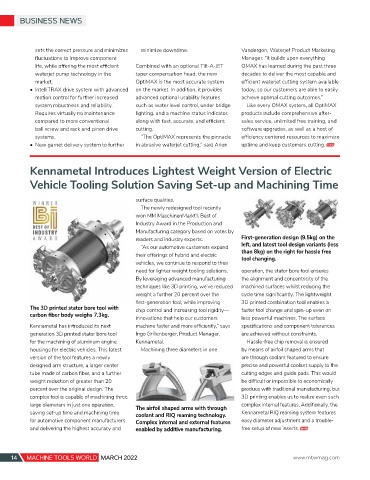

readers and industry experts. First-generation design (9.5kg) on the

“As our automotive customers expand left, and latest tool design variants (less

their offerings of hybrid and electric than 8kg) on the right for hassle free

tool changing.

vehicles, we continue to respond to their

need for lighter weight tooling solutions. operation, the stator bore tool ensures

By leveraging advanced manufacturing the alignment and concentricity of the

techniques like 3D printing, we’ve reduced machined surfaces whilst reducing the

weight a further 20 percent over the cycle time significantly. The lightweight

first-generation tool, while improving 3D printed combination tool enables a

The 3D printed stator bore tool with chip control and increasing tool rigidity— faster tool change and spin-up even on

carbon fiber body weighs 7.3kg. innovations that help our customers less powerful machines. The surface

Kennametal has introduced its next machine faster and more efficiently,” says specifications and component tolerances

generation 3D printed stator bore tool Ingo Grillenberger, Product Manager, are achieved without constraints.

for the machining of aluminum engine Kennametal. Hassle-free chip removal is ensured

housings for electric vehicles. This latest Machining three diameters in one by means of airfoil shaped arms that

version of the tool features a newly are through coolant featured to ensure

designed arm structure, a larger center precise and powerful coolant supply to the

tube made of carbon fiber, and a further cutting edges and guide pads. This would

weight reduction of greater than 20 be difficult or impossible to economically

percent over the original design. The produce with traditional manufacturing, but

complex tool is capable of machining three 3D printing enables us to realize even such

large diameters in just one operation, The airfoil shaped arms with through complex internal features. Additionally, the

saving set-up time and machining time coolant and RIQ reaming technology. Kennametal RIQ reaming system features

for automotive component manufacturers Complex internal and external features easy diameter adjustment and a trouble-

and delivering the highest accuracy and enabled by additive manufacturing. free setup of new inserts.

14 MACHINE TOOLS WORLD MARCH 2022 www.mtwmag.com