Page 52 - MTW NOVEMBER 2021 - Digital Magazine_Neat

P. 52

TECH INNOVATION

Complete machining of

truck camshafts proves its worth

Effective complete machining of DAF camshafts for commercial vehicles is based on the sophisticated interplay

between highperformance linear motors, ultra-precise in-process measuring systems and easily accessible

components. The Dutch truck manufacturer is extending its camshaft machining operations by adding the

modular concept on the new platform 6.

omfortable furnishings, long maintenance intervals and

excellent driving dynamics are the reasons for purchasing

Creliable DAF trucks. DAF praises its customers with the

highest level of efficiency, maximum driving comfort and a high

residual value.

The precisely machined camshafts ensure that the engines

of commercial vehicles function faultlessly and constantly

for a high mileage. With the JUCAM 6L, these are machined

efficiently and ultra precisely in a single clamping set-up. “The

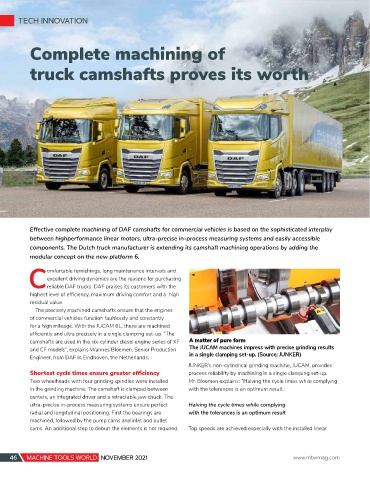

camshafts are used in the six-cylinder diesel engine series of XF A matter of pure form

and CF models”, explains Wannes Bloemen, Senior Production The JUCAM machines impress with precise grinding results

Engineer, from DAF in Eindhoven, the Netherlands. in a single clamping set-up. (Source: JUNKER)

JUNKER‘s non-cylindrical grinding machine, JUCAM, provides

Shortest cycle times ensure greater efficiency process reliability by machining in a single clamping set-up.

Two wheelheads with four grinding spindles were installed Mr. Bloemen explains: “Halving the cycle times while complying

in the grinding machine. The camshaft is clamped between with the tolerances is an optimum result.:

centers, an integrated driver and a retractable jaw chuck. The

ultra-precise in-process measuring systems ensure perfect Halving the cycle times while complying

radial and longitudinal positioning. First the bearings are with the tolerances is an optimum result

machined, followed by the pump cams and inlet and outlet

cams. An additional step to deburr the elements is not required. Top speeds are achieved especially with the installed linear

46 MACHINE TOOLS WORLD NOVEMBER 2021 www.mtwmag.com