Page 60 - MTW NOVEMBER 2021 - Digital Magazine_Neat

P. 60

TECH INNOVATION

How to Prevent

Deformed Parts

During ALUMINUM

MACHINING

Emily Newton is the Editor-in-Chief of Revolutionized. She has over four years experience

covering the industrial sector.

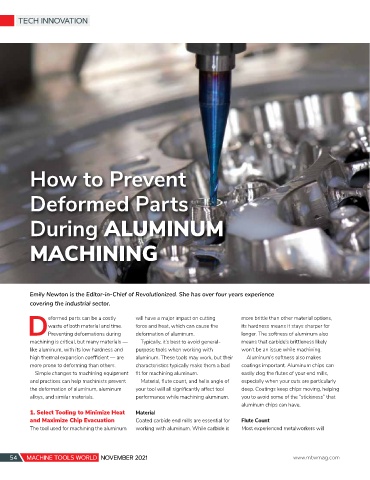

eformed parts can be a costly will have a major impact on cutting more brittle than other material options,

waste of both material and time. force and heat, which can cause the its hardness means it stays sharper for

DPreventing deformations during deformation of aluminum. longer. The softness of aluminum also

machining is critical, but many materials — Typically, it’s best to avoid general- means that carbide’s brittleness likely

like aluminum, with its low hardness and purpose tools when working with won’t be an issue while machining.

high thermal expansion coefficient — are aluminum. These tools may work, but their Aluminum’s softness also makes

more prone to deforming than others. characteristics typically make them a bad coatings important. Aluminum chips can

Simple changes to machining equipment fit for machining aluminum. easily clog the flutes of your end mills,

and practices can help machinists prevent Material, flute count, and helix angle of especially when your cuts are particularly

the deformation of aluminum, aluminum your tool will all significantly affect tool deep. Coatings keep chips moving, helping

alloys, and similar materials. performance while machining aluminum. you to avoid some of the “stickiness” that

aluminum chips can have.

1. Select Tooling to Minimize Heat Material

and Maximize Chip Evacuation Coated carbide end mills are essential for Flute Count

The tool used for machining the aluminum working with aluminum. While carbide is Most experienced metalworkers will

54 MACHINE TOOLS WORLD NOVEMBER 2021 www.mtwmag.com