Page 44 - MTW November 2022 Digital Magazine_R1

P. 44

TECH INNOVATION

being clamped properly is due to the there is no workpiece or there is a gap due such as the power wing (PW) series, pull

accumulation of chips on the jaws or to improper seating or clamping, the air lock (PU/PUB/LU) series and finger (FG)

on the locator seating area. Some chips will leak through the hole or gap, resulting series. These chucks are characterized by

may be left on these surfaces even after in pressure loss. This difference in pressure a pull-back function which is an essential

cleaning. There are other reasons as will be sensed by a pressure switch, feature for air sensing to work. These

well, such as loading errors due to the generally called the ‘air catch sensor’. chucks pull the workpiece towards the

difference in clamping dimensions, the This air catch sensor will detect the gap locator, ensuring positive butting.

tilting of the workpiece due to its self- between locator and the workpiece. If Kitagawa M-Series and Y-RE-Series

weight just before clamping with a large gap is more than the set value, it will cylinders are available with built-in

jaw- stroke chuck or due to complex send the feedback to the machine about rotary joints to pass the air from a static

shapes of workpieces and so on. the improper clamping. We can set the pneumatic module to a work holding

allowable gap value as low as 10 microns, solution rotating at a high speed. These

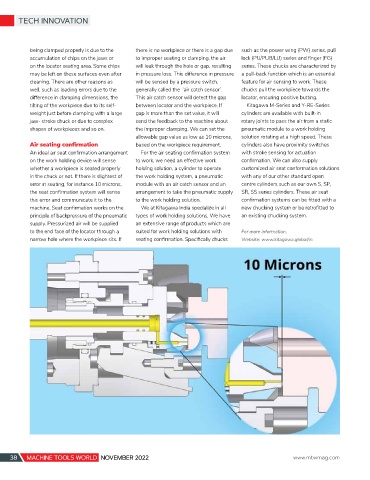

Air seating confirmation based on the workpiece requirement. cylinders also have proximity switches

An ideal air seat confirmation arrangement For the air seating confirmation system with stroke sensing for actuation

on the work holding device will sense to work, we need an effective work confirmation. We can also supply

whether a workpiece is seated properly holding solution, a cylinder to operate customized air seat conformation solutions

in the chuck or not. If there is slightest of the work holding system, a pneumatic with any of our other standard open

error in seating, for instance 10 microns, module with an air catch sensor and an centre cylinders such as our own S, SP,

the seat confirmation system will sense arrangement to take the pneumatic supply SR, SS series cylinders. These air seat

this error and communicate it to the to the work holding solution. confirmation systems can be fitted with a

machine. Seat confirmation works on the We at Kitagawa India specialize in all new chucking system or be retrofitted to

principle of backpressure of the pneumatic types of work holding solutions. We have an existing chucking system.

supply. Pressurized air will be supplied an extensive range of products which are

to the end face of the locator through a suited for work holding solutions with For more information,

narrow hole where the workpiece sits. If seating confirmation. Specifically chucks Website: www.kitagawa.global/in

38 MACHINE TOOLS WORLD NOVEMBER 2022 www.mtwmag.com