Page 2 - Manufacturing Heroes 2022

P. 2

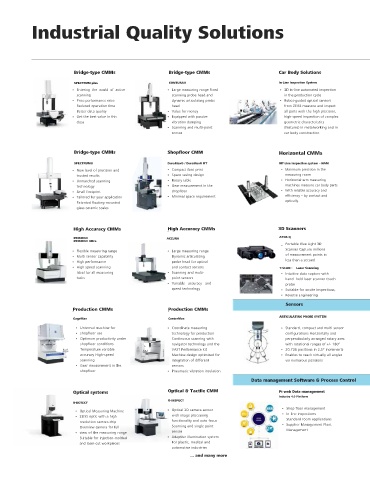

Industrial Quality Solutions

Bridge-type CMMs Bridge-type CMMs Car Body Solutions Computed Tomography Roundness / Form & Cylindricity Measuring Machines

SPECTRUM plus CONTURA® In-Line Inspection System METROTOM: CT

Entering the world of active Large measuring range Fixed 3D in-line automated inspection Traceable 3D X-Ray Measurements

SURFCOM Touch 50 SURFCOM CREST

scanning scanning probe head and in the production cycle Very high resolution for measuring

Price performance ratio dynamic articulating probe Robot-guided optical sensors components with narrow tolerance Compact design High accuracy Roughness &

Reduced operation time head from ZEISS measure and inspect or small defects Built-in printer Contour measurement in

Better data quality Value for money all parts with the high precision, High-performance system for Large LCD - single trace

Get the best value in this Equipped with passive high-speed inspection of complex irradiating thicker and multi- Easy reading Linear motor technology in X-

class vibration damping geometric characteristics material parts USB axis

Scanning and multi-point (features) in metalworking and in Assembly Analysis, Porosity and Connectivity Laser sensor with 0.31nm

sensor car body construction. defect analysis Battery / Power resolution

operation High speed & wide measuring

range

Auto tilting of driver unit by

Bridge-type CMMs Shopfloor CMM Horizontal CMMs High Accuracy CMMs ±45°

SPECTRUM® DuraMax® / DuraMax® RT Off-Line inspection system – HAM XENOS RONDCOM NEX 200 RONDCOM 73A

New level of precision and Compact foot print Maximum precision in the Maximum rigidity for Diameter measurement - 2W and 4 W parts – Block/

trusted results Space saving design measuring room maximum precision and Patented Head/ Crank

Unmatched scanning Rotary table Horizontal-arm measuring reproducibility Taper measurement High rotational accuracy

technology Gear measurement in the machines measure car body parts Innovative mechanical design Spiral Cylindricity 0.06um

Small footprint shopfloor With reliable accuracy and First use for linear drives in CAM Lobe profile Auto centering & tilting

Tailored for your application Minimal space requirement efficiency – by contact and reference measuring machines analysis Lead / Twist 400 Kg Loading capacity

optically.

Patented floating mounted LED status display analysis Roughness 1 Meter Stroke

glass ceramic scales New VAST gold probe for measurement

maximum accuracy and

reproducibility

High Accuracy CMMs High Accuracy CMMs 3D Scanners Large CMMs

®

PRISMO® ACCURA ATOS Q MMZ Series CONTOURECORD 1600G SURFCOM NEX 030

PRISMO® Ultra

Portable Blue Light 3D

For complex large & heavy parts Auto element judgment ( Al Linear motor technology in

Scanner Capture millions

Flexible measuring range Large measuring range High level of accuracy at every Function) X- axis Wide measuring

of measurement points in

Multi sensor capability Dynamic articulating measuring point Dimension display function range – 60 mm in Z axis

High performance probe head for optical less than a second Rotary table for symmetric parts / Profile synthesis function Quick magnetic arm change

High speed scanning and contact sensors T-SCAN - Laser Scanning Gear measurements Peak and valley function Twin stylus for diameter

Ideal for all measuring Scanning and multi- Intuitive data capture with Used in machinery, wind Calculation point repeat measurement

tasks point sensors hand- held laser scanner touch turbines, automotive and function Collision protection

Variable accuracy and probe aerospace industries Temperature compensation

speed technology Suitable for onsite Inspections,

Reverse Engineering

Sensors Sensors Industrial Microscopes

Production CMMs Production CMMs

® ®

VAST

ARTICULATING PROBE SYSTEM Axiovert A1 MAT Stemi 508

GageMax CenterMax

Latest technology Inverted Latest Apochromatic

Universal machine for Coordinate measuring Standard, compact and multi-sensor Single-point and scanning, microscope for all corrected Stereo microscope with

shopfloor use technology for production configurations Horizontally and self- centering measuring Metallurgical Analysis 8: 1 Zoom.

Optimum productivity under Continuous scanning with perpendicularly arranged rotary axes High speed continuous Magnifications : Ranging Magnifications : Ranging between

shopfloor conditions navigator technology and the with rotational ranges of +/- 180° scanning between 12.5x – 1000x 1.9x – 100x

Temperature variable VAST Performance Kit 20,736 positions in 2.5° increments Stylus: Weight upto 800gms Electronically Coded Latest Hi-Power LED Ring

accuracy High-speed Machine design optimized for Enables to reach virtually all angles Length upto 800mm Nosepiece with automatic and Focus Illuminations with

scanning integration of different via numerous positions Flexible styli combinations scaling controller.

Gear measurement in the sensors Various Contrast techniques– Stand options for various samples

shopfloor Pneumatic vibration insulation BF, DF, POL & DIC options Light types : Regular, Boom and Swing

Manager enables automatic Arm types. Digital Network options

Data management Software & Process Control Software & Process Control

Intensity for all magnifications with Wi-Fi router with iPad option.

Optical systems Optical & Tactile CMM Pi web Data management ZEISS Reverse Engineering (ZRE) Software, Automated EVO 18

Industry 4.0 Platform A perfect solution for your reverse engineering Particle Analyzer for your quality EVO 18 can handle specimens of

O-INSPECT needs

O-DETECT control of component and oil up to 250 mm in diameter and 145

Optical Measuring Machine Optical 2D camera sensor Shop floor management Surface reconstruction cleanliness - Particle Size upto 2 mm in height

ZEISS optic with a high with image processing In line inspections Tool correction Volume micron Perfect for industrial needs

resolution camera chip functionality and auto focus Standard room applications calculation Compliance to Cleanliness Resolution: 3 nm (2 nm) @ 30 kV

standards ISO 16232, VDA 19.1

Supplier Management Plant

Overview camera for full Scanning and single point Management Easy- to-use interface & Oil analysis ISO 4406 & 4407 SE and W (LaB6); <10nm @3 kV

view of the measuring range sensor and NAS 1638. HV mode; Magnification: 5x to

Suitable for injection-molded Adaptive illumination system Automatic analysis : Distribution 1,000,000x;

and laser-cut workpieces For plastic, medical and

automotive industries size, Classification of Metal, Non-

metal & Fiberous

... and many more ... and many more ... and many more

Mail us at: info.metrology.in@zeiss.com