Page 131 - YG 2019

P. 131

DREAM DRILLS DREAM DRILLS

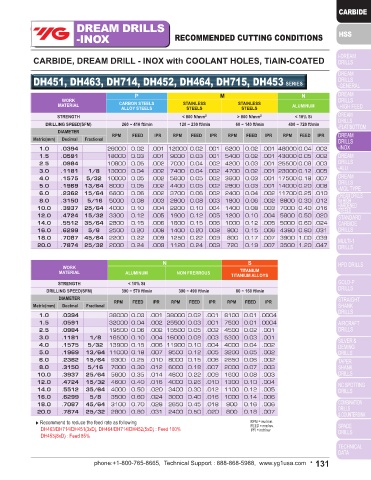

-INOX DH453 SERIES -INOX RECOMMENDED CUTTING CONDITIONS

CARBIDE, DREAM DRILL - INOX with COOLANT HOLES EXTRA LONG CARBIDE, DREAM DRILL - INOX with COOLANT HOLES, TiAIN-COATED

▶Special flute shape and geometry suitable for machining stainless steel

▶Excellent chip evacuation from better surface treatment DH451, DH463, DH714, DH452, DH464, DH715, DH453 SERIES

▶Point R-thinning achieves superior centering and chip curling

▶TiAlN coating for better surface finishes and longer tool life P M N

WORK

MATERIAL CARBON STEELS STAINLESS STAINLESS ALUMINUM

ALLOY STEELS STEELS STEELS

D2 D1 STRENGTH < 800 N/mm 2 > 800 N/mm 2 < 10% Si

L1 DRILLING SPEED(SFM) 260 ~ 410 ft/min 120 ~ 230 ft/min 60 ~ 140 ft/min 490 ~ 720 ft/min

DIAMETER

L2 RPM FEED IPR RPM FEED IPR RPM FEED IPR RPM FEED IPR

Metric(mm) Decimal Fractional

1.0 .0394 26000 0.02 .001 12000 0.02 .001 6200 0.02 .001 48000 0.04 .002

1.5 .0591 18000 0.03 .001 9000 0.03 .001 5400 0.02 .001 43000 0.05 .002

2.5 .0984 10800 0.05 .002 7000 0.04 .002 4200 0.03 .001 25500 0.08 .003

1/8

140 20 bar P.131 8 × D 3.0 .1181 5/32 13000 0.04 .002 7400 0.04 .002 4700 0.02 .001 23000 0.12 .005

.002 5600

10000

0.05 .002 3600

4.0

.1575

0.05

0.03 .001 17500 0.18 .007

Unit : mm 5.0 .1969 13/64 8000 0.05 .002 4400 0.05 .002 2800 0.03 .001 14000 0.20 .008

Drill Diameter Drill Diameter 6.0 .2362 15/64 6600 0.06 .002 3700 0.06 .002 2400 0.04 .002 11700 0.25 .010

EDP No. Shank Flute Overall EDP No. Shank Flute Overall 8.0 .3150 5/16 5000 0.08 .003 2800 0.08 .003 1800 0.06 .002 8800 0.30 .012

Metric Fractional Decimal Diameter Length Length Metric Fractional Decimal Diameter Length Length

TiAlN D1 D2 L1 L2 TiAlN D1 D2 L1 L2 10.0 .3937 25/64 4000 0.10 .004 2200 0.10 .004 1400 0.08 .003 7000 0.40 .016

12.0 .4724 15/32 3300 0.12 .005 1900 0.12 .005 1200 0.10 .004 5800 0.50 .020

DH453154 15.4 .6063 16 152 203 DH453178 17.8 .7008 18 171 222 14.0 .5512 35/64 2800 0.15 .006 1600 0.15 .006 1000 0.12 .005 5000 0.60 .024

DH453155 15.5 .6102 16 152 203 DH453179 17.9 .7047 18 171 222

DH453156 15.6 .6142 16 152 203 DH453180 18.0 .7087 18 171 222 16.0 .6299 5/8 2500 0.20 .008 1400 0.20 .008 900 0.15 .006 4380 0.80 .031

DH453157 15.7 .6181 16 152 203 DH453181 18.1 .7126 20 190 243 18.0 .7087 45/64 2200 0.22 .009 1250 0.22 .009 800 0.17 .007 3900 1.00 .039

DH453158 15.8 .6220 16 152 203 DH453182 18.2 .7165 20 190 243 20.0 .7874 25/32 2000 0.24 .009 1120 0.24 .009 720 0.19 .007 3500 1.20 .047

DH453040F 15.875 5/8 .6250 16 152 203 DH453183 18.3 .7205 20 190 243

DH453159 15.9 .6260 16 152 203 DH453184 18.4 .7244 20 190 243 N S

DH453160 16.0 .6299 16 152 203 DH453185 18.5 .7283 20 190 243 WORK TITANIUM

DH453161 16.1 .6339 18 171 222 DH453186 18.6 .7323 20 190 243 MATERIAL ALUMINUM NON FRERROUS TITANIUM ALLOYS

DH453162 16.2 .6378 18 171 222 DH453187 18.7 .7362 20 190 243 STRENGTH < 10% Si

DH453163 16.3 .6417 18 171 222 DH453188 18.8 .7402 20 190 243 DRILLING SPEED(SFM) 390 ~ 570 ft/min 390 ~ 490 ft/min 80 ~ 160 ft/min

DH453164 16.4 .6457 18 171 222 DH453189 18.9 .7441 20 190 243 DIAMETER

DH453165 16.5 .6496 18 171 222 DH453190 19.0 .7480 20 190 243 Metric(mm) Decimal Fractional RPM FEED IPR RPM FEED IPR RPM FEED IPR

DH453166 16.6 .6535 18 171 222 DH453048F 19.050 3/4 .7500 20 190 243

DH453167 16.7 .6575 18 171 222 DH453191 19.1 .7520 20 190 243 1.0 .0394 38000 0.03 .001 38000 0.02 .001 8100 0.01 .0004

DH453168 16.8 .6614 18 171 222 DH453192 19.2 .7559 20 190 243 1.5 .0591 32000 0.04 .002 25500 0.03 .001 7500 0.01 .0004

DH453169 16.9 .6654 18 171 222 DH453193 19.3 .7598 20 190 243 2.5 .0984 19500 0.06 .002 15500 0.05 .002 4500 0.02 .001

DH453170 17.0 .6693 18 171 222 DH453194 19.4 .7638 20 190 243 3.0 .1181 1/8 18500 0.10 .004 16000 0.08 .003 5300 0.03 .001

DH453171 17.1 .6732 18 171 222 DH453195 19.5 .7677 20 190 243 4.0 .1575 5/32 13900 0.15 .006 11900 0.10 .004 4000 0.04 .002

DH453172 17.2 .6772 18 171 222 DH453196 19.6 .7717 20 190 243 5.0 .1969 13/64 11000 0.18 .007 9500 0.12 .005 3200 0.05 .002

DH453173 17.3 .6811 18 171 222 DH453197 19.7 .7756 20 190 243 6.0 .2362 15/64 9300 0.25 .010 8000 0.15 .006 2650 0.06 .002

DH453174 17.4 .6850 18 171 222 DH453198 19.8 .7795 20 190 243 8.0 .3150 5/16 7000 0.30 .012 6000 0.18 .007 2000 0.07 .003

DH453175 17.5 .6890 18 171 222 DH453199 19.9 .7835 20 190 243 10.0 .3937 25/64 5600 0.35 .014 4800 0.22 .009 1600 0.08 .003

DH453176 17.6 .6929 18 171 222 DH453200 20.0 .7874 20 190 243

DH453177 17.7 .6968 18 171 222 12.0 .4724 15/32 4600 0.40 .016 4000 0.26 .010 1300 0.10 .004

14.0 .5512 35/64 4000 0.50 .020 3400 0.30 .012 1100 0.12 .005

▶ Other shank types are available on your request. 16.0 .6299 5/8 3500 0.60 .024 3000 0.40 .016 1000 0.14 .006

18.0 .7087 45/64 3100 0.70 .028 2650 0.45 .018 900 0.16 .006

20.0 .7874 25/32 2800 0.80 .031 2400 0.50 .020 800 0.18 .007

◎ : Excellent ◯ : Good

P H M K N S ▶ Recommend to reduce the feed rate as following RPM = rev./min.

Carbon Prehardened DH463/DH714/DH451(3xD), DH464/DH714/DH452(5xD) : Feed 100% FEED = mm/rev.

Steels Alloy Steels Steels Hardened Steels Stainless Cast Iron Aluminum Copper Bronze CFRP Titanium IPR = inch/rev

Steels

~HB225 HB225~325 HRc30~45 HRc45~55 HRc55~ DH453(8xD) : Feed 85%

◎ ◎ ○ ◎ ○ ○

130 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 131