Page 263 - YG 2019

P. 263

NC SPOTTING NC SPOTTING

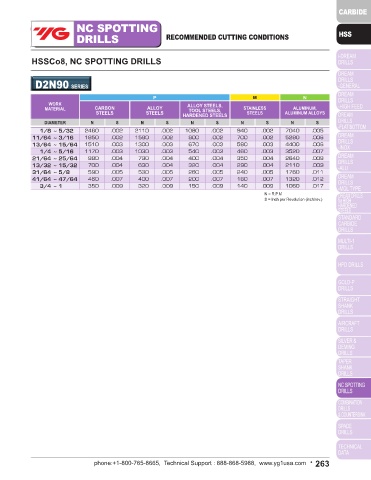

DRILLS D2N90 SERIES DRILLS RECOMMENDED CUTTING CONDITIONS

HSSCo8, NC SPOTTING DRILLS HSSCo8, NC SPOTTING DRILLS

▶Application : For more precise centering work on NC/CNC machine. A larger diameter in respect to the subsequent drilling tool permit to obtain

the centering and chamfering simultaneously.

D2N90 SERIES

P M N

WORK

90° MATERIAL CARBON ALLOY ALLOY STEELS, STAINLESS ALUMINUM,

TOOL STEELS,

D1 STEELS STEELS HARDENED STEELS STEELS ALUMINUM ALLOYS

L1 DIAMETER N S N S N S N S N S

120° L2 1/8 ~ 5/32 2460 .002 2110 .002 1080 .002 940 .002 7040 .005

11/64 ~ 3/16 1850 .002 1580 .002 800 .002 700 .002 5280 .006

13/64 ~ 15/64 1510 .003 1300 .003 670 .003 580 .003 4400 .006

1/4 ~ 5/16 1170 .003 1030 .003 540 .003 460 .003 3520 .007

21/64 ~ 25/64 880 .004 790 .004 400 .004 350 .004 2640 .008

90 120 P.263 13/32 ~ 15/32 700 .004 630 .004 320 .004 290 .004 2110 .009

31/64 ~ 5/8 590 .005 530 .005 260 .005 240 .005 1760 .011

NC Spotting drills 90° NC Spotting drills 120°

Unit : Inch 41/64 ~ 47/64 460 .007 400 .007 200 .007 180 .007 1320 .012

Diameter Flute Overall Diameter Flute Overall 3/4 ~ 1 350 .009 320 .009 150 .009 140 .009 1060 .017

EDP No. Length Length EDP No. Length Length N = R.P.M

D1 L1 L2 D1 L1 L2 S = Inch per Revolution (inch/rev.)

0081L 1/8 .472 1.93 2081L 1/8 .472 1.93

0121L 3/16 .590 2.44 2121L 3/16 .590 2.44

0161L 1/4 .669 2.76 2161L 1/4 .669 2.76

0201L 5/16 .984 3.11 2201L 5/16 .984 3.11

0241L 3/8 .827 3.50 2241L 3/8 .827 3.50

0321L 1/2 .984 4.02 2321L 1/2 .984 4.02

0401L 5/8 1.575 4.53 2401L 5/8 1.575 4.53

0481L 3/4 1.968 5.16 2481L 3/4 1.968 5.16

0641L 1 1.968 6.14 2641L 1 1.968 6.14

* Individually packaged

◎ : Excellent ◯ : Good

P H M K N S

Carbon Alloy Steels Prehardened Hardened Steels

Steels Steels Stainless Cast Iron Aluminum Copper Bronze CFRP Titanium

Steels

~HB225 HB225~325 HRc30~45 HRc45~55 HRc55~

◎ ◎ ○ ○ ○

262 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 263