Page 504 - YG 2019

P. 504

SCREW THREAD SCREW THREAD

INSERT TAPS ST/SI SERIES INSERT TAPS T7436 SERIES

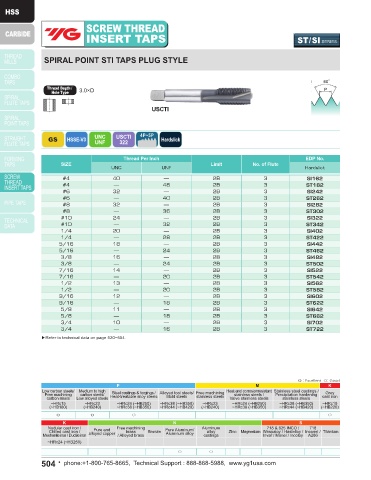

SPIRAL POINT STI TAPS PLUG STYLE

SPIRAL POINT STI TAPS PLUG STYLE

for General Purpose

Thread Depth / 3.0×D Thread Depth / 3.0×D

Hole Type Hole Type

USCTI

USCTI

GS HSS UNC USCTI 4P~5P Bright

UNF

322

GS HSSE-V3 UNC USCTI 4P~5P Hardslick

UNF

322

Thread Per Inch EDP No.

SIZE Limit No. of Flute

Thread Per Inch EDP No. UNC UNF Bright

SIZE Limit No. of Flute

UNC UNF Hardslick #2 56 — H2 2 T7436082

#3 48 — H2 2 T7436122

#4 40 — 2B 3 SI162 #4 40 — H1 2 T7436161

#4 — 48 2B 3 ST182 #4 40 — H2 2 T7436162

#6 32 — 2B 3 SI242 #4 — 48 H2 2 T7436182

#6 — 40 2B 3 ST262 #5 40 — H2 2 T7436202

#8 32 — 2B 3 SI282 #6 32 — H2 2 T7436242

—

#8 — 36 2B 3 ST302 #6 32 40 H3 2 T7436243

T7436262

—

H2

2

#6

#10 24 — 2B 3 SI322 #8 32 — H2 2 T7436282

#10 — 32 2B 3 ST342 #8 32 — H3 2 T7436283

1/4 20 — 2B 3 SI402 #8 — 36 H2 2 T7436302

1/4 — 28 2B 3 ST422 #10 24 — H2 2 T7436322

5/16 18 — 2B 3 SI442 #10 24 — H3 2 T7436323

5/16 — 24 2B 3 ST462 #10 — 32 H2 2 T7436342

3/8 16 — 2B 3 SI482 #10 — 32 H3 2 T7436343

3/8 — 24 2B 3 ST502 1/4 20 — H2 3 T7436402

—

7/16 14 — 2B 3 SI522 1/4 20 28 H3 3 T7436403

1/4

3

T7436422

—

H2

7/16 — 20 2B 3 ST542 1/4 — 28 H3 3 T7436423

1/2 13 — 2B 3 SI562 5/16 18 — H3 3 T7436443

1/2 — 20 2B 3 ST582 5/16 18 — H4 3 T7436444

9/16 12 — 2B 3 SI602 5/16 — 24 H2 3 T7436462

9/16 — 18 2B 3 ST622 5/16 — 24 H3 3 T7436463

5/8 11 — 2B 3 SI642 3/8 16 — H3 3 T7436483

5/8 — 18 2B 3 ST662 3/8 16 — H4 3 T7436484

3/4 10 — 2B 3 SI702 3/8 — 24 H2 3 T7436502

H3

3

24

—

T7436503

3/8

3/4 — 16 2B 3 ST722

7/16 14 — H3 3 T7436523

▶Refer to technical data on page 520~554. 7/16 14 — H4 3 T7436524

7/16 — 20 H3 3 T7436543

7/16 — 20 H4 3 T7436544

1/2 13 — H3 4 T7436563

1/2 13 — H4 4 T7436564

1/2 — 20 H3 4 T7436583

1/2 — 20 H4 4 T7436584

◎ : Excellent ○: Good ▶Refer to technical data on page 520~554. ◎ : Excellent ○: Good

P M K P M K

Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey

Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron

carbon steels Low alloyed steels Valve stainless steels stainless steels carbon steels Low alloyed steels Valve stainless steels stainless steels

~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19 ~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19

(~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220) (~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220)

◎ ◎ ○ ○ ○ ○ ○

K N S K N S

Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718 Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718

Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium

Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286 Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286

~HRc24 (~HB250) ~HRc24 (~HB250)

○ ○ ○ ○

504 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 505