Page 10 - CMA PROfiles Spring 2015

P. 10

DK Cabinets … continued from page 9 “There are so many people in the CMA with wealth of knowledge

who are willing to share it with you, whether in seminars or online in

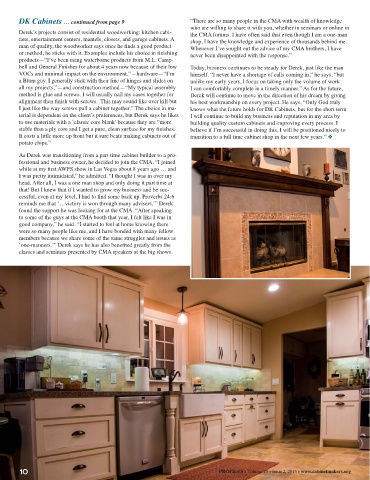

Derek’s projects consist of residential woodworking: kitchen cabi-

the CMA forums. I have often said that even though I am a one-man

nets, entertainment centers, mantels, closets, and garage cabinets. A shop, I have the knowledge and experience of thousands behind me.

man of quality, the woodworker says once he finds a good product Whenever I’ve sought out the advice of my CMA brothers, I have

or method, he sticks with it. Examples include his choice in finishing

never been disappointed with the response.”

products—“I’ve been using waterborne products from M.L. Camp-

bell and General Finishes for about 4 years now because of their low Today, business continues to be steady for Derek, just like the man

VOCs and minimal impact on the environment,”—hardware—“I’m himself. “I never have a shortage of calls coming in,” he says, “but

a Blum guy. I generally stick with their line of hinges and slides on unlike my early years, I focus on taking only the volume of work

all my projects,”—and construction method—“My typical assembly I can comfortably complete in a timely manner.” As for the future,

method is glue and screws. I will usually nail my cases together for Derek will continue to move in the direction of his dream by giving

alignment then finish with screws. This may sound like over kill but his best workmanship on every project. He says, “Only God truly

I just like the way screws pull a cabinet together.” The choice in ma- knows what the future holds for DK Cabinets, but for the short term

terial is dependent on the client’s preferences, but Derek says he likes I will continue to build my business and reputation in my area by

to use materials with a ‘classic core blank’ because they are “more building quality custom cabinets and improving every process. I

stable than a ply core and I get a pure, clean surface for my finishes. believe if I’m successful in doing this, I will be positioned nicely to

It costs a little more up front but it sure beats making cabinets out of transition to a full time cabinet shop in the next few years.” ❖

potato chips.”

As Derek was transitioning from a part time cabinet builder to a pro-

fessional and business owner, he decided to join the CMA. “I joined

while at my first AWFS show in Las Vegas about 8 years ago … and

I was pretty intimidated,” he admitted. “I thought I was in over my

head. After all, I was a one man shop and only doing it part time at

that! But I knew that if I wanted to grow my business and be suc-

cessful, even at my level, I had to find some back up. Proverbs 24:6

reminds me that ‘…victory is won through many advisers.’” Derek

found the support he was looking for at the CMA. “After speaking

to some of the guys at the CMA booth that year, I felt like I was in

good company,” he said. “I started to feel at home knowing there

were so many people like me, and I have bonded with many fellow

members because we share some of the same struggles and issues as

‘one-manners.’” Derek says he has also benefited greatly from the

classes and seminars presented by CMA speakers at the big shows.

10 PROFILES • Volume 15 • Issue 2, 2015 • www.cabinetmakers.org