Page 4 - Fanar

P. 4

210,00 210,00

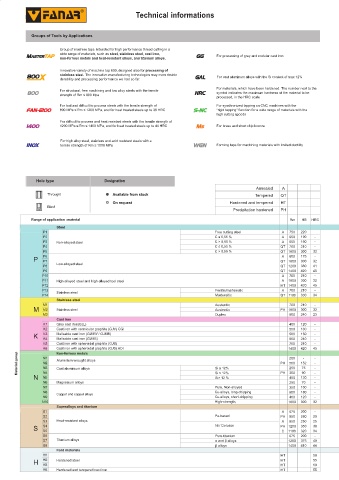

Technical informations

Groups of Tools by Applications

Group of machine taps intended for high performance thread cutting in a

wide range of materials, such as steel, stainless steel, cast iron,

MASTERTAP non-ferrous metals and heat-resistant alloys, and titanium alloys. GG For processing of grey and nodular cast iron

Innovative variety of machine tap 800, designed also for processing of

800 stainless steel. The innovative manufacturing technologies may even double GAL For cast aluminum alloys with the Si content of max 12%

durability and processing performance we had so far.

For materials, which have been hardened. The number next to the

For structural, free machining and low alloy steels with the tensile

800 strength of Rm ≤ 800 Mpa HRC symbol indicates the maximum hardness of the material to be

processed, in the HRC scale

For tool and difficult to process steels with the tensile strength of For synchronized tapping on CNC machines with the

FAN-1200 800 MPa ≤ Rm ≤ 1200 MPa, and for heat treated steels up to 38 HRC S-NC "rigid tapping" function for a wide range of materials with the

high cutting speeds

For difficult to process and heat resistant steels with the tensile strength of

1400 1200 MPa ≤ Rm ≤ 1400 MPa, and for heat treated steels up to 44 HRC Ms For brass and short chip bronze

For high alloy steel, stainless and acid resistant steels with a

INOX tensile strength of Rm ≤ 1000 MPa WGN Forming taps for machining materials with limited ductility

Hole type Designation

Annealed A

Throught Available from stock Tempered QT

On request Hardened and tempered HT

Blind

Precipitation hardened PH

Range of application -material Rm HB HRC

Steel

P1 Free cutting steel A 750 220

P1

P2 C ≤ 0,55 % A 650 190 -

P2

P3

P3 Non-alloyed steel C > 0,55 % A 650 190 -

P4

P4 C ≤ 0,55 % QT 700 210 -

P5

P5 C > 0,55 % QT 1000 300 32

P6 A 600 175 -

P6

P P7 QT 1000 300 32

P7

Low-alloyed steel

P8 QT 1200 380 41

P8

P9

P9 QT 1400 420 45

P10

P10 A 700 210 -

P11

P1 1 High-alloyed steel and high-alloyed tool steel A 1000 300 32

P12

P12 HT 1400 420 45

P13

P13 Ferritic/martensitic A 700 210 -

Stainless steel

P14

P14 Martensitic QT 1100 330 34

Stainless steel

M1

M1 Austenitic 700 210 -

M M2 Stainless steel Austenitic PH 1000 300 32

M2

M3

M3 Duplex 800 240 23

Cast iron

K1

K1 Grey cast iron(GJL) 400 120 -

K2

K2 Cast iron with vermicular graphite (GJV) CGI 550 160 -

K3

K K3 Malleable cast iron (GJMW / GJMB) 500 150 - -

Malleable cast iron (GJMB)

K4

240

K4

800

K5

K5 Cast iron with spheroidal graphite (GJS) 700 210 -

K6 Cast iron with spheroidal graphite (GJS) ADI 1400 420 45

K6

Material group N1 Cast aluminium alloys Si ≤ 12% PH 200 152 - - -

Non-ferrous metals

N1

-

Aluminium wrought alloys

N2

N2

500

N3

N3

75

250

N4

90

N N4 Si ≤ 12% PH 300 130 - -

Si> 12 %

450

N5

N5

N6 Magnesium alloys 250 70 -

N6

N7 Pure, Non-alloyed 350 100 -

N7

N8

N8 Cu-alloys, long-chipping 600 180 -

Copper and copper alloys

N9

N9 Cu-alloys, short-chipping 400 120 -

N10

N10 High-strength, 1000 300 32

Superalloys and titanium

S1

S1 A 675 200 -

S2

S2 Fe-based PH 950 280 29

S3

S3 Heat-resistant alloys A 850 250 25

S4

S S4 Ni / Co base PH 1200 350 38

S5 C 1100 320 34

S5

S6 Pure titanium 675 200 -

S6

S7

S7 Titanium alloys α and β alloys 1250 375 40

S8

S8 β alloys 1400 410 44

Hard materials

H1

H1 HT 50

H2

H H2 Hardened steel HT 55

H3

60

H3

HT

4 H4 Hardened and tempered cast iron HT 55

H4

195,00

195,00