Page 13 - Blade (January 2019)

P. 13

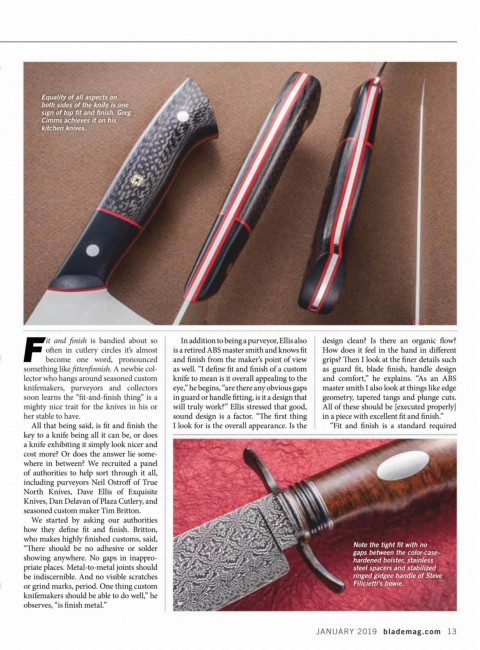

Equality of all aspects on

both sides of the knife is one

sign of top fi t and fi nish. Greg

Cimms achieves it on his

kitchen knives.

it and fi nish is bandied about so In addition to being a purveyor, Ellis also design clean? Is there an organic fl ow?

often in cutlery circles it’s almost is a retired ABS master smith and knows fi t How does it feel in the hand in diff erent

F become one word, pronounced and fi nish from the maker’s point of view grips? Then I look at the finer details such

something like fi ttenfi nnish. A newbie col- as well. “I defi ne fit and finish of a custom as guard fit, blade finish, handle design

lector who hangs around seasoned custom knife to mean is it overall appealing to the and comfort,” he explains. “As an ABS

knifemakers, purveyors and collectors eye,” he begins, “are there any obvious gaps master smith I also look at things like edge

soon learns the “fi t-and-finish thing” is a in guard or handle fitting, is it a design that geometry, tapered tangs and plunge cuts.

mighty nice trait for the knives in his or will truly work?” Ellis stressed that good, All of these should be [executed properly]

her stable to have. sound design is a factor. “Th e fi rst thing in a piece with excellent fit and fi nish.”

All that being said, is fit and fi nish the I look for is the overall appearance. Is the “Fit and finish is a standard required

key to a knife being all it can be, or does

a knife exhibiting it simply look nicer and

cost more? Or does the answer lie some-

where in between? We recruited a panel

of authorities to help sort through it all,

including purveyors Neil Ostroff of True

North Knives, Dave Ellis of Exquisite

Knives, Dan Delavan of Plaza Cutlery, and

seasoned custom maker Tim Britton.

We started by asking our authorities

how they defi ne fit and fi nish. Britton,

who makes highly finished customs, said,

Note the tight fi t with no

“There should be no adhesive or solder

gaps between the color-case-

showing anywhere. No gaps in inappro- hardened bolster, stainless

priate places. Metal-to-metal joints should steel spacers and stabilized

be indiscernible. And no visible scratches ringed gidgee handle of Steve

or grind marks, period. One thing custom Filicietti’s bowie.

knifemakers should be able to do well,” he

observes, “is fi nish metal.”

JANUARY 2019 blademag.com 13