Page 428 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 428

The City & Guilds Textbook: Plumbing Book 1

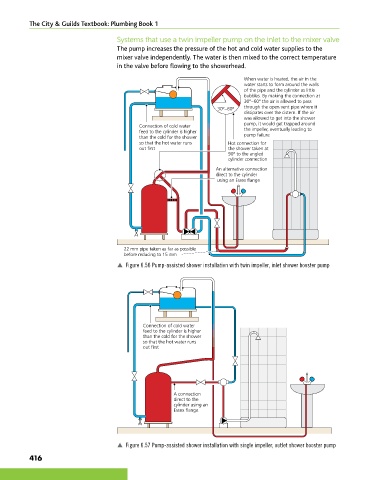

Systems that use a twin impeller pump on the inlet to the mixer valve

The pump increases the pressure of the hot and cold water supplies to the

mixer valve independently. The water is then mixed to the correct temperature

in the valve before flowing to the showerhead.

When water is heated, the air in the

water starts to form around the walls

of the pipe and the cylinder as little

bubbles. By making the connection at

30º−60º the air is allowed to pass

30º−60º through the open vent pipe where it

dissipates over the cistern. If the air

was allowed to get into the shower

pump, it would get trapped around

Connection of cold water

feed to the cylinder is higher the impeller, eventually leading to

than the cold for the shower pump failure

so that the hot water runs Hot connection for

out first the shower taken at

90º to the angled

cylinder connection

An alternative connection

direct to the cylinder

using an Essex flange

22 mm pipe taken as far as possible

before reducing to 15 mm

p Figure 6.56 Pump-assisted shower installation with twin impeller, inlet shower booster pump

Connection of cold water

feed to the cylinder is higher

than the cold for the shower

so that the hot water runs

out first

A connection

direct to the

cylinder using an

Essex flange

p Figure 6.57 Pump-assisted shower installation with single impeller, outlet shower booster pump

416

9781510416482.indb 416 29/03/19 9:02 PM