Page 678 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 678

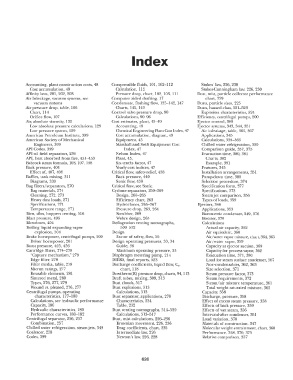

Index

Accounting, plant construction costs, 48 Compressible fluids, 101, 102-112 Stokes' law, 226, 230

Cost accumulation, 49 Calculation, 112 Stokes-Cunningham law, 226, 230

Affinity laws, 201, 202, 203 Pressure drop, chart, 102, 103, 111 Dust, mist, particle collector performance

Air In leakage, vacuum systems, see Computer aided drafting, 17 chart, 229

vacuum systems Condensate, flashing flow, 135-142, 147 Dusts, particle sizes, 225

Air pressure drop, table, 106 Charts, 142, 143 Dusts, hazard class, 521-523

Chart, 114 Control valve pressure drop, 90 Explosion characteristics, 524

Orifice flow, 107 Calculations, 90-96 Efficiency, centrifugal pumps, 200

Air, absolute viscosity, 132 Cost estimates, plant, 45--49 Ejector control, 380

Low absolute pressure calculations, 129 Accounting, 48 Ejector systems, 343, 344, 351

Low pressure system, 129 Chemical Engineering Plant Cost Index, 47 Air inleakage, table, 366, 367

American Petroleum Institute, 399 Cost accumulation, diagram, 49 Applications, 345

American Society of Mechanical Equipment, 45 Calculations, 359-366

Engineers, 399 Marshall and Swift Equipment Cost Chilled water refrigeration, 350

API Codes, 399 Index,47 Comparison guide, 357, 375

API oil field separators, 239 Nelson Index, 47 Evacuation time, 380, 381

API, heat absorbed from fire, 451-453 Plant, 45, Charts, 382

Babcock steam formula, 103, 107, 108 Six-tenths factor, 4 7 Example, 381

Back pressure, 401 Yearly cost indices, 4 7 Features, 345

Effect of, ,107, 108 Critical flow, safety-relief, 438 Installation arrangements, 351

Baffles, Lank mixing, 31 l Back pressure, 440 Pump-down time, 380

Diagrams, 330 Sonic flow, 138 Selection procedure, 374

Bag filters/separators, 270 Critical flow, see Sonic Specification form, 377

Bag materials, 274 Cyclone separators, 259-269 Specifications, 373

Cleaning, 272, 273 Design. 260-265 Steam jet comparison, 356

Heavy dust loads, 271 Efficiency chart, 263 Types of loads, 359

Specifications, 271 Hydroclones, 265-267 Ejectors, 346

Temperature range, 271 Pressure drop, 263, 261 Applications, 353

Bins, silos, hoppers venting, 516 Scrubber, 269 Barometric condenser, 249, 376

Blast pressure, 496 Webre design, 265 Booster, 370

Blowdown, 404 Deflagration venting nomographs, Calculations

Boiling liquid expanding vapor 509-512 Actual air capacity, 362

explosion, 504 Design Air equivalent, 360

Brake horsepower, centrifugal pumps, 200 Factor of safety, flow, 56 A.ir/water vapor mixture, chart, 364, 365

Driver horsepower, 201 Design operating pressures, 33, 34 Air/water vapor, 359

Burst pressure, 405, 456 Guide, 36 Capacity at ejector suction, 369

Cartridge filters, 274-278 Maximum operating pressure, 33 Capacity for process vapor, 362

"Capture mechanism," 279 Diaphragm metering pump, 214 Evacuation time, 371, 380

Edge filter, 278 DIERS,finalreports,523 Load for steam surface condenser, 367

Filter media, table, 278 Discharge coefficients, liquid flow, C,, Non-condensables, 362, 363

Micron ratings, 277 chart, 118 Size selection, 371

Reusable elements, 281 Dowtherm(R) pressure drop, charts, 94, 113 Steam pressure factor, 373

Sintered metal, 280 Draft tubes, mixing, 309, 313 Steam requirements, 372

Types, 276, 277, 279 Dust clouds, 517 Steam/air mixture temperature, 361

Wound vs. pleated, 276, 277 Dust explosions, 513 Total weight saturated mixture, 362

Centrifugal pumps, operating Calculations, 513 Capacity, 358

characteristics, 177-180 Dust separator, applications, 278 Discharge, pressure, 358

Calculations, see hydraulic performance Characteristics, 234 Effect of excess steam pressure, 358

Capacity, 180 Table, 232 Effects of back pressure, 359

Hydraulic characteristics, 180 Dust venting nomographs, 514-520 Effects of wet steam, 356

Performance curves, 180-182 Calculations, 513-517 Inter-and-after condenser, 351

Centrifugal separator, 256, 257 Dust, mist calculations, 226--236 Load variation, 370

Combination, 257 Brownian movement, 226, 236 Materials of construction, 347

Chilled water refrigeration, steamjets, 349 Drag coefficients, chart, 235 Molecular weight. entrainment, chart, 360

Coalescer, 258 Intermediate law, 226 Performance, 358, 370, 375

Codes, 399 Newton's law, 226, 228 Relative comparison, 357

626