Page 47 - MACHINE TOOLS WORLD MARCH 2022 Digital Magazine

P. 47

#FIBER LASER TECHNOLOGY TECH INNOVATION

laser technology has made it unnecessary

to have any particular training in order

to operate the equipment. Even unlikely

conventional welding technology there

is no requirement of setup for fiber laser

welding machines. They can be simply

transported to the job site.

Welding systems based on fiber laser

technology are the most cost-effective.

There is no requirement for filler material.

Even with this technology, the majority

of health and environmental risks during

welding have been eradicated. Fiber laser

welding has good welding effect, i.e.,

small heat affected area, no deformation,

firm welding, all with an attractive look,

for industries where good aesthetic look

matters but also needs firm weld.

Because no filler metals or consumable

goods are needed, and heat penetration is

regulated, this method saves a lot of time

and energy by eliminating the pre- and

post-grinding processes. This equipment,

according to Mehta Cad Cam, can speed

up welding processes by 2 to 3 times

compared to old or conventional welding

technologies.

It was difficult to weld aluminium

or other tough metals, even welding

on dissimilar metals was challenging

or welding low-thickness metals also

proved tough job. With Mehta’s fiber laser

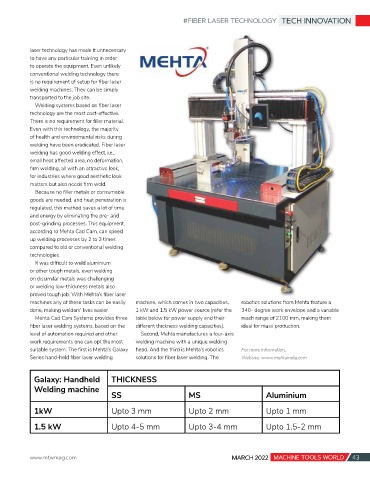

machines any of these tasks can be easily machine, which comes in two capacities, robotics solutions from Mehta feature a

done, making welders’ lives easier. 1 kW and 1.5 kW power source (refer the 340- degree work envelope and a variable

Mehta Cad Cam Systems provides three table below for power supply and their reach range of 2100 mm, making them

fiber laser welding systems, based on the different thickness welding capacities). ideal for mass production.

level of automation required and other Second, Mehta manufactures a four-axis

work requirements one can opt the most welding machine with a unique welding

suitable system. The first is Mehta’s Galaxy head. And the third is Mehta’s robotics For more information,

Series hand-held fiber laser welding solutions for fiber laser welding. The Website: www.mehtaindia.com

Galaxy: Handheld THICKNESS

Welding machine

SS MS Aluminium

1kW Upto 3 mm Upto 2 mm Upto 1 mm

1.5 kW Upto 4-5 mm Upto 3-4 mm Upto 1.5-2 mm

www.mtwmag.com MARCH 2022 MACHINE TOOLS WORLD 43