Page 58 - MACHINE TOOLS WORLD - DECEMBER 2021

P. 58

TECH INNOVATION

How simultaneous

high-current and

high-frequency

has positioned the

ANCA EDG

as the benchmark for

PCD manufacture

oly Crystalline Diamond (PCD) products are widely When machining these materials, PCD tooling exhibits superior

used in industry for their superior abrasion resistance wear resistance, heat tolerance and tool longevity.

Pand longevity when machining non-ferrous materials. Using PCD in tooling is not new, however, the explosion of

By virtue of their uniform carbon lattice structures, diamond is lightweight materials used in all industries as manufacturers

the hardest material available and therefore lends itself well to race to create lightweight and durable products highlights how

manufacturing processes requiring high speeds, feed rates and versatile PCD tooling is becoming. Aluminium and composite

extended wear behaviours. PCD is not typically used to machine products continue to grow quickly with the rapid expansion of

ferrous materials such as iron or steel due to a chemical reaction consumer electronics, light-weight transportation and more

that occurs between the diamond and the iron molecules. The efficient power generation.

Carbon atoms in the diamond react with the Iron (Ferrous) Linked to the growth in non-ferrous componentry and PCD

atoms of the iron or steel to produce Iron Carbide (Fe3C), tooling is the downward pressure being applied to machine tool

causing the tool edges to collapse. However, it can tackle builders. Lowering cycle times and increasing surface finishes

bimetal applications involving aluminium and cast iron. enables a profitable business proposition for PCD tooling

The areas that PCD tooling excels in is the machining of non- manufacturers by reducing manufacturing costs per tool and

ferrous materials, composites, electronic components, timbers increasing quality and durability for the end user.

and precious metals. To enable ANCA’s customers to create high-quality, low-

cost tooling the new ANCA Motion SparX Generator has been

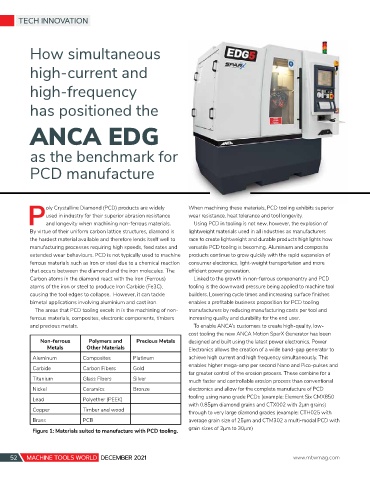

Non-ferrous Polymers and Precious Metals designed and built using the latest power electronics. Power

Metals Other Materials Electronics allows the creation of a wide band-gap generator to

Aluminum Composites Platinum achieve high current and high frequency simultaneously. This

Carbide Carbon Fibers Gold enables higher mega-amp per second Nano and Pico-pulses and

far greater control of the erosion process. These combine for a

Titanium Glass Fibers Silver much faster and controllable erosion process than conventional

Nickel Ceramics Bronze electronics and allow for the complete manufacture of PCD

Lead Polyether (PEEK) tooling using nano grade PCDs (example: Element Six CMX850

with 0.85µm diamond grains and CTX002 with 2µm grains)

Copper Timber and wood through to very large diamond grades (example: CTH025 with

Brass PCB average grain size of 25µm and CTM302 a multi-modal PCD with

Figure 1: Materials suited to manufacture with PCD tooling. grain sizes of 2µm to 30µm)

52 MACHINE TOOLS WORLD DECEMBER 2021 www.mtwmag.com