Page 60 - MACHINE TOOLS WORLD - DECEMBER 2021

P. 60

TECH INNOVATION

Additionally, by virtue of the 5-axis kinematics of the ANCA edges are very important in the manufacture of aluminium and

EDG machines utilising a rotary copper electrode, almost infinite composites as they reduce burring while increasing surface

tool geometries can be created including complex end-face finishes. In composites, keen cutting edges also reduce the risk of

and fluting geometries. This linked to very aggressive pricing delamination during machining.

and performance with supreme flexibility enables tooling

manufacturers to create high quality PCD tools competitively.

Additionally, with the increase in performance, decrease in cycle

time and increase in surface finish specification, users are able

to purchase arguably the most technologically advanced erosion

machine available. ANCA is the only supplier of EDG erosion

machines in the market that has a synchronized, adaptable,

intelligent and controllable erosion process suited perfectly to the

vast array of non-ferrous materials.

To highlight these benefits, ANCA conducted testing between

tools created on an ANCA EDG, tools created on a competitor

laser machine and lastly on a competitor erosion machine.

Testing utilised a 12mm 2D shear brazed (neutral rake face) tool

due to laser ablation systems being unable to create large fluted

tools. The PCD material was Element Six CTM302. Figure 4: Cutting edge created on ANCA EDG. Notice the

Testing showed definitively that not only did the ANCA EDG keen cutting edge.

match the quality and cycle time of laser created tools, but it was

vastly superior to the like-for-like erosion results.

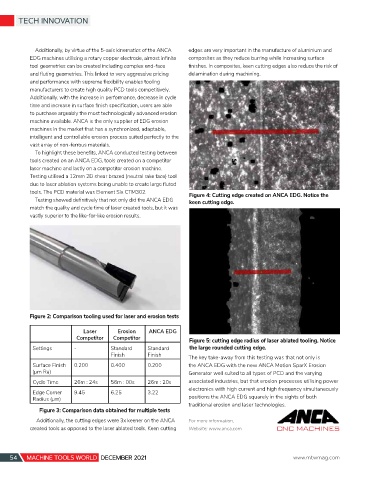

Figure 2: Comparison tooling used for laser and erosion tests

Laser Erosion ANCA EDG

Competitor Competitor Figure 5: cutting edge radius of laser ablated tooling. Notice

Settings - Standard Standard the large rounded cutting edge.

Finish Finish The key take-away from this testing was that not only is

Surface Finish 0.200 0.400 0.200 the ANCA EDG with the new ANCA Motion SparX Erosion

(µm Ra) Generator well suited to all types of PCD and the varying

Cycle Time 26m : 24s 56m : 00s 26m : 20s associated industries, but that erosion processes utilising power

electronics with high current and high frequency simultaneously

Edge Corner 9.45 6.25 3.22

Radius (µm) positions the ANCA EDG squarely in the sights of both

traditional erosion and laser technologies.

Figure 3: Comparison data obtained for multiple tests

Additionally, the cutting edges were 3x keener on the ANCA For more information,

created tools as opposed to the laser ablated tools. Keen cutting Website: www.anca.com

54 MACHINE TOOLS WORLD DECEMBER 2021 www.mtwmag.com