Page 57 - Manufacturing Heroes 2022

P. 57

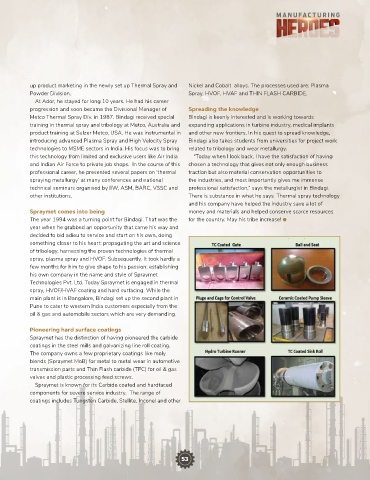

up product marketing in the newly set up Thermal Spray and Nickel and Cobalt alloys. The processes used are: Plasma

Powder Division. Spray, HVOF, HVAF and THIN FLASH CARBIDE.

At Ador, he stayed for long 10 years. He had his career

progression and soon became the Divisional Manager of Spreading the knowledge

Metco Thermal Spray Div. in 1987. Bindagi received special Bindagi is keenly interested and is working towards

training in thermal spray and tribology at Metco, Australia and expanding applications in turbine industry, medical implants

product training at Sulzer Metco, USA. He was instrumental in and other new frontiers. In his quest to spread knowledge,

introducing advanced Plasma Spray and High Velocity Spray Bindagi also takes students from universities for project work

technologies to MSME sectors in India. His focus was to bring related to tribology and wear metallurgy.

this technology from limited and exclusive users like Air India “Today when I look back, I have the satisfaction of having

and Indian Air Force to private job shops. In the course of this chosen a technology that gives not only enough business

professional career, he presented several papers on ‘thermal traction but also material conservation opportunities to

spraying metallurgy’ at many conferences and national the industries, and most importantly gives me immense

technical seminars organised by IIW, ASM, BARC, VSSC and professional satisfaction,” says the metallurgist in Bindagi.

other institutions. There is substance in what he says. Thermal spray technology

and his company have helped the industry save a lot of

Spraymet comes into being money and materials and helped conserve scarce resources

The year 1994 was a turning point for Bindagi. That was the for the country. May his tribe increase!

year when he grabbed an opportunity that came his way and

decided to bid adieu to service and start on his own, doing

something closer to his heart: propagating the art and science

of tribology, harnessing the proven technologies of thermal

spray, plasma spray and HVOF. Subsequently, It took hardly a

few months for him to give shape to his passion: establishing

his own company in the name and style of Spraymet

Technologies Pvt. Ltd. Today Spraymet is engaged in thermal

spray, HVOF/HVAF coating and hard surfacing. While the

main plant is in Bangalore, Bindagi set up the second plant in

Pune to cater to western India customers especially from the

oil & gas and automobile sectors which are very demanding.

Pioneering hard surface coatings

Spraymet has the distinction of having pioneered the carbide

coatings in the steel mills and galvanizing line roll coating.

The company owns a few proprietary coatings like moly

blends (Spraymet MoB) for metal to metal wear in automotive

transmission parts and Thin Flash carbide (TFC) for oil & gas

valves and plastic processing feed screws.

Spraymet is known for its Carbide coated and hardfaced

components for severe service industry. The range of

coatings includes Tungsten Carbide, Stellite, Inconel and other

53