Page 21 - E BOOK ENGINE MECHANICAL M2

P. 21

3. TURBOCHARGER

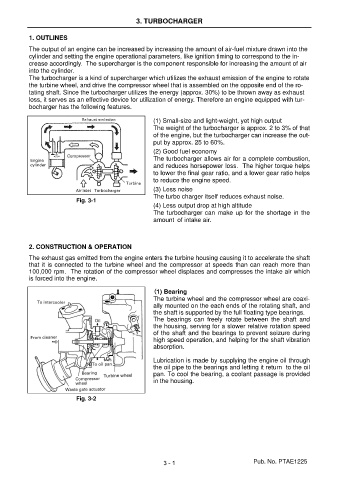

1. OUTLINES

The output of an engine can be increased by increasing the amount of air-fuel mixture drawn into the

cylinder and setting the engine operational parameters, like ignition timing to correspond to the in-

crease accordingly. The supercharger is the component responsible for increasing the amount of air

into the cylinder.

The turbocharger is a kind of supercharger which utilizes the exhaust emission of the engine to rotate

the turbine wheel, and drive the compressor wheel that is assembled on the opposite end of the ro-

tating shaft. Since the turbocharger utilizes the energy (approx. 30%) to be thrown away as exhaust

loss, it serves as an effective device for utilization of energy. Therefore an engine equipped with tur-

bocharger has the following features.

(1) Small-size and light-weight, yet high output

The weight of the turbocharger is approx. 2 to 3% of that

of the engine, but the turbocharger can increase the out-

put by approx. 25 to 60%.

(2) Good fuel economy

The turbocharger allows air for a complete combustion,

and reduces horsepower loss. The higher torque helps

to lower the final gear ratio, and a lower gear ratio helps

to reduce the engine speed.

(3) Less noise

The turbo charger itself reduces exhaust noise.

Fig. 3-1

(4) Less output drop at high altitude

The turbocharger can make up for the shortage in the

amount of intake air.

2. CONSTRUCTION & OPERATION

The exhaust gas emitted from the engine enters the turbine housing causing it to accelerate the shaft

that it is connected to the turbine wheel and the compressor at speeds than can reach more than

100,000 rpm. The rotation of the compressor wheel displaces and compresses the intake air which

is forced into the engine.

( (( (1) Bearing

The turbine wheel and the compressor wheel are coaxi-

ally mounted on the each ends of the rotating shaft, and

the shaft is supported by the full floating type bearings.

The bearings can freely rotate between the shaft and

the housing, serving for a slower relative rotation speed

of the shaft and the bearings to prevent seizure during

high speed operation, and helping for the shaft vibration

absorption.

Lubrication is made by supplying the engine oil through

the oil pipe to the bearings and letting it return to the oil

pan. To cool the bearing, a coolant passage is provided

in the housing.

Fig. 3-2

3 - 1 Pub. No. PTAE1225