Page 25 - E BOOK ENGINE MECHANICAL M2

P. 25

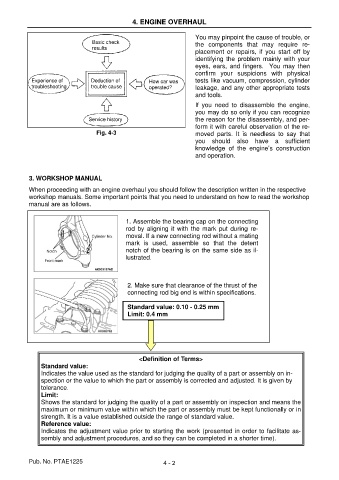

4. ENGINE OVERHAUL

You may pinpoint the cause of trouble, or

Basic check the components that may require re-

results

placement or repairs, if you start off by

identifying the problem mainly with your

eyes, ears, and fingers. You may then

confirm your suspicions with physical

Experience of Deduction of How car was tests like vacuum, compression, cylinder

troubleshooting trouble cause operated? leakage, and any other appropriate tests

and tools.

If you need to disassemble the engine,

you may do so only if you can recognize

Service history the reason for the disassembly, and per-

form it with careful observation of the re-

Fig. 4-3 moved parts. It is needless to say that

you should also have a sufficient

knowledge of the engine’s construction

and operation.

3. WORKSHOP MANUAL

When proceeding with an engine overhaul you should follow the description written in the respective

workshop manuals. Some important points that you need to understand on how to read the workshop

manual are as follows.

1. Assemble the bearing cap on the connecting

rod by aligning it with the mark put during re-

moval. If a new connecting rod without a mating

mark is used, assemble so that the detent

notch of the bearing is on the same side as il-

lustrated.

2. Make sure that clearance of the thrust of the

connecting rod big end is within specifications.

Standard value: 0.10 - 0.25 mm

Limit: 0.4 mm

<Definition of Terms>

Standard value:

Indicates the value used as the standard for judging the quality of a part or assembly on in-

spection or the value to which the part or assembly is corrected and adjusted. It is given by

tolerance.

Limit:

Shows the standard for judging the quality of a part or assembly on inspection and means the

maximum or minimum value within which the part or assembly must be kept functionally or in

strength. It is a value established outside the range of standard value.

Reference value:

Indicates the adjustment value prior to starting the work (presented in order to facilitate as-

sembly and adjustment procedures, and so they can be completed in a shorter time).

Pub. No. PTAE1225 4 - 2