Page 1013 - YG 2019

P. 1013

V7 PLUS A V7 PLUS A

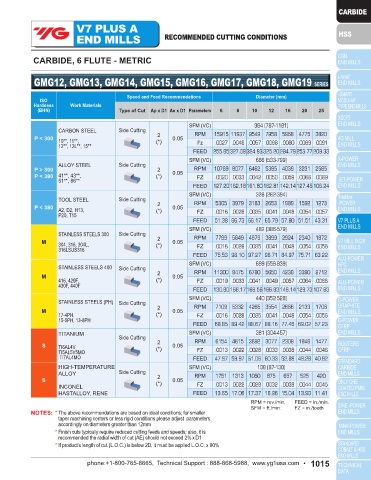

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

CARBIDE, 4 FLUTE - METRIC CARBIDE, 6 FLUTE - METRIC

UGMG55, UGMG56 SERIES GMG12, GMG13, GMG14, GMG15, GMG16, GMG17, GMG18, GMG19 SERIES

Speed and Feed Recommendations Diameter (mm) Speed and Feed Recommendations Diameter (mm)

ISO ISO

Hardness Work Materials Type of Ap x Ae x Hardness Work Materials

(BHN) Parameters 3 4 5 6 8 10 12 16 18 20 25 (BHN) Type of Cut Ap x D1 Ae x D1 Parameters 6 8 10 12 16 20 25

Cut D1 D1

SFM (VC) 531 (425-638) SFM (VC) 984 (787-1181)

CARBON STEEL RPM CARBON STEEL Side Cutting RPM

2

P < 300 10**, 11**, 1 0.5 171891289210313 8594 6446 5157 4297 3223 2865 2578 2063 P < 300 10**, 11**, (*) 0.05 15915 11937 9549 7958 5968 4775 3820

12**, 12L**, 15** Fz .0010 .0011 .0012 .0016 .0024 .0026 .0028 .0030 .0031 .0035 .0039 12**, 12L**, 15** Fz .0027 .0046 .0057 .0068 .0080 .0089 .0091

FEED 67.67 54.81 48.72 54.14 60.90 52.78 47.37 38.07 36.09 36.54 32.16 FEED 255.65 327.08 324.83 325.20 284.79 253.77 209.33

SFM (VC) 371 (297-445) SFM (VC) 666 (533-799)

ALLOY STEEL ALLOY STEEL Side Cutting

P > 300 1 0.5 RPM 11990 8992 7194 5995 4496 3597 2997 2248 1998 1798 1439 P > 300 2 0.05 RPM 10769 8077 6462 5385 4039 3231 2585

P < 380 41**, 43**, FZ .0010 .0011 .0012 .0016 .0024 .0026 .0028 .0029 .0031 .0035 .0039 P < 380 41**, 43**, (*) FZ .0020 .0033 .0042 .0050 .0059 .0066 .0069

51**, 86** 51**, 86**

FEED 47.20 38.23 33.99 37.76 42.48 36.82 33.04 26.20 24.86 25.49 22.43 FEED 127.20 162.18 161.80 162.81 142.14 127.45 106.24

SFM (VC) 223 (178-268) SFM (VC) 328 (262-394)

TOOL STEEL RPM 7215 5411 4329 3608 2706 2165 1804 1353 1203 1082 866 TOOL STEEL Side Cutting RPM 5305 3979 3183 2653 1989 1592 1273

2

P < 380 A2, D2, H13, 1 0.5 P < 380 A2, D2, H13, (*) 0.05

P20, T15 FZ .0007 .0007 .0008 .0011 .0017 .0018 .0019 .0020 .0022 .0025 .0028 P20, T15 FZ .0016 .0028 .0035 .0041 .0048 .0054 .0057

FEED 19.32 16.19 14.32 15.91 17.90 15.34 13.92 11.08 10.60 10.74 9.54 FEED 51.38 66.73 66.17 65.79 57.80 51.51 43.31

SFM (VC) 390 (312-469) SFM (VC) 482 (386-579)

CAST IRON RPM STAINLESS STEELS 300 Side Cutting RPM

K < 260 1 0.5 12626 9470 7576 6313 4735 3788 3157 2367 2104 1894 1515 M 2 0.05 7799 5849 4679 3899 2924 2340 1872

GRAY, MALLEABLE, FZ .0012 .0013 .0015 .0020 .0029 .0032 .0034 .0037 .0039 .0044 .0049 304, 316, 304L, (*) FZ .0016 .0028 .0035 .0041 .0048 .0054 .0056

DUCTILE 316LSUS316

FEED 61.64 49.21 44.14 49.71 55.18 48.32 43.25 34.67 32.81 33.40 29.59 FEED 75.53 98.10 97.27 96.71 84.97 75.71 63.22

STAINLESS STEELS SFM (VC) 279 (223-335) STAINLESS STEELS 400 Side Cutting SFM (VC) 699 (559-839)

300 RPM 9019 6764 5411 4509 3382 2706 2255 1691 1503 1353 1082 2 RPM 11300 8475 6780 5650 4238 3390 2712

M 1 0.5 M 0.05

304, 316, 304L, FZ .0008 .0008 .0010 .0016 .0018 .0020 .0022 .0024 .0025 .0026 .0027 416, 420F, (*) FZ .0019 .0033 .0041 .0049 .0057 .0064 .0066

316LSUS316 430F, 440F

FEED 28.41 21.30 21.30 29.12 23.97 21.30 19.53 15.98 15.15 13.85 11.59 FEED 130.80 168.17 166.56 166.83 146.14 129.73 107.63

STAINLESS STEELS SFM (VC) 253 (202-303) SFM (VC) 440 (352-528)

400 RPM 8170 6127 4902 4085 3064 2451 2042 1532 1362 1225 980 STAINLESS STEELS (PH) Side Cutting 2 RPM 7109 5332 4265 3554 2666 2133 1706

M 1 0.5 M 17-4PH, (*) 0.05

416, 420F, FZ .0006 .0006 .0010 .0012 .0016 .0018 .0020 .0021 .0023 .0023 .0023 15-5PH, 13-8PH FZ .0016 .0028 .0035 .0041 .0048 .0054 .0056

430F, 440F FEED 19.30 14.47 19.30 19.30 19.30 17.37 16.08 13.03 12.65 11.19 9.11 FEED 68.85 89.42 88.67 88.16 77.46 69.02 57.23

STAINLESS STEELS SFM (VC) 253 (202-303) TITANIUM SFM (VC) 381 (304-457)

(PH) RPM 8170 6127 4902 4085 3064 2451 2042 1532 1362 1225 980 Side Cutting 2 RPM 6154 4615 3692 3077 2308 1846 1477

M 1 0.5 S TI6AL4V (*) 0.05

17-4PH, FZ .0008 .0008 .0010 .0016 .0018 .0020 .0022 .0024 .0025 .0026 .0027 TI5AL5V5MO FZ .0013 .0022 .0028 .0033 .0038 .0044 .0046

15-5PH, 13-8PH FEED 25.73 19.30 19.30 26.38 21.71 19.30 17.69 14.47 13.72 12.54 10.50 TI7AL4MO FEED 47.97 59.97 61.06 60.33 52.88 49.28 40.82

TITANIUM SFM (VC) 154 (123-185) HIGH-TEMPERATURE SFM (VC) 108 (87-130)

RPM 4987 3740 2992 2493 1870 1496 1247 935 831 748 598 ALLOY Side Cutting 2 RPM 1751 1313 1050 875 657 525 420

S TI6AL4V 0.3 0.5 S 0.05

TI5AL5V5MO FZ .0007 .0007 .0009 .0015 .0016 .0018 .0019 .0021 .0023 .0023 .0024 INCONEL (*) FZ .0013 .0022 .0028 .0032 .0038 .0044 .0045

TI7AL4MO FEED 14.14 10.60 10.37 14.53 11.78 10.60 9.62 7.95 7.59 6.83 5.75 HASTALLOY, RENE FEED 13.65 17.06 17.37 16.96 15.04 13.90 11.41

HIGH-TEMPERATURE SFM (VC) 69 (55-83) RPM = rev./min. FEED = in./min.

ALLOY RPM 2228 1671 1337 1114 836 668 557 418 371 334 267 SFM = ft./min. FZ = in./tooth

S 0.3 0.2 NOTES: * The above recommendations are based on ideal conditions; for smaller

INCONEL FZ .0006 .0006 .0007 .0011 .0012 .0014 .0015 .0017 .0018 .0018 .0019 taper machining centers or less rigid conditions please adjust parameters

accordingly on diameters greater than 12mm

HASTALLOY, RENE FEED 4.91 3.68 3.58 4.91 4.08 3.68 3.33 2.76 2.63 2.37 2.02

* Finish cuts typically require reduced cutting feeds and speeds; also, it is

RPM = rev./min. FEED = in./min. recommended the radial width of cut (AE) should not exceed 2% x D1

Ap

SFM = ft./min. FZ = in./tooth * If product’s length of cut (L.O.C.) is below 2D, it must be applied L.O.C. x 90%

Ae See notes on next page

1014 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1015