Page 23 - YG 2019

P. 23

(Reference page

CASE STUDY 4G MILLS END MILLS (Reference page : p.661 ~ p.845) CASE STUDY TitaNox-POWER END MILLS : p.957 ~ p.976)

◆

◆

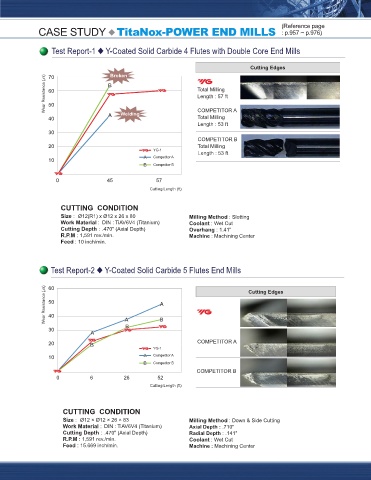

TEST REPORT (Ball) YG-1 (Total Cutting Length : 984 ft) Test Report-1 ◆ Y-Coated Solid Carbide 4 Flutes with Double Core End Mills

Cutting Edges

100 70 Broken

90 Wear Resistance (㎛) 60 Total Milling

Length : 57 ft

Point part 20。 part 20。 part

80 50

COMPETITOR A (Total Cutting Length : 984 ft) Welding COMPETITOR A

40 Total Milling

70 Length : 53 ft

30

60

COMPETITOR B

20 Total Milling

50 Point part 20。 part 20。 part YG-1 Length : 53 ft

Wear 10 Competitor A

40 CUTTING CONDITION Competitor B

Tool : 2Flute, Carbide Ball End Mill

30 Size : Ø6×6×12×90 0 45 57

Work Material : KP4M (HRc35 / AISI P20+Ni DIN 1.2738 Improved) Cutting Length (ft)

20 Cutting Speed : 426.7 ft/min.

R.P.M : 6,900 rev./min.

Feed : 32.68 inch/min.

10 CUTTING CONDITION

Feed per tooth : .0024 inch/tooth

Milling Method : Profiling Size : Ø12(R1) x Ø12 x 26 x 80 Milling Method : Slotting

0 Milling Depth : Axial : .0079″ Work Material : DIN : TiAV6V4 (Titanium) Coolant : Wet Cut

0 82 246 410 656 984 Radial : .0472″ Cutting Depth : .470" (Axial Depth) Overhang : 1.41"

Total Cutting Length (ft) Coolant : Oil Mist R.P.M : 1,591 rev./min. Machine : Machining Center

Overhang : 1.024″ Feed : 10 inch/min.

TEST REPORT (Corner Radius)

YG-1 (Total Cutting Length : 570 ft) Test Report-2 ◆ Y-Coated Solid Carbide 5 Flutes End Mills

80 60 Cutting Edges

Wear Resistance (㎛)

70 50

Peripheral teeth 40

60 COMPETITOR A (Total Cutting Length : 570 ft)

30

50 COMPETITOR A

20

YG-1

Competitor A

Wear 40 Peripheral teeth 10 Competitor B

COMPETITOR B

30 CUTTING CONDITION 0 6 26 52

Tool : 4Flute, Carbide Corner Radius End Mill Cutting Length (ft)

20 Size : Ø10(R0.5)×10×25×100

Work Material : KP4M (HRc35 / AISI P20+Ni DIN 1.2738 Improved)

Cutting Speed : 169 ft/min.

10 R.P.M : 1,640 rev./min. CUTTING CONDITION

Feed : 7.09 inch/min.

Feed per tooth : .0011 inch/tooth Size : Ø12 × Ø12 × 26 × 83 Milling Method : Down & Side Cutting

0 Milling Method : Down & Side Cutting Work Material : DIN : TiAV6V4 (Titanium) Axial Depth : .710"

0 95 190 380 570 Milling Depth : Axial : .9842″ Cutting Depth : .470" (Axial Depth) Radial Depth : .141"

Total Cutting Length (ft) Radial : .0197″ R.P.M : 1,591 rev./min. Coolant : Wet Cut

Coolant : Oil Mist Feed : 15.669 inch/min. Machine : Machining Center

Overhang : 1.614″