Page 473 - YG 2019

P. 473

STRAIGHT STRAIGHT

FLUTE TAPS TR SERIES FLUTE TAPS TR SERIES

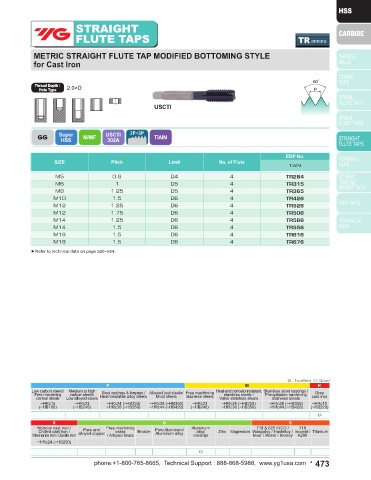

STRAIGHT FLUTE TAP MODIFIED BOTTOMING STYLE METRIC STRAIGHT FLUTE TAP MODIFIED BOTTOMING STYLE

for Cast Iron for Cast Iron

Thread Depth / 2.0×D Thread Depth / 2.0×D

Hole Type Hole Type

USCTI USCTI

GG Super M/MF USCTI 2P~3P TiAIN GG Super M/MF USCTI 2P~3P TiAIN

HSS

302A

HSS

302A

Thread Per Inch EDP No. EDP No.

SIZE Limit No. of Flute SIZE Pitch Limit No. of Flute

UNC UNF TiAlN TiAlN

#10 24 — H3 4 TR323 M5 0.8 D4 4 TR284

#10 24 — H5 4 TR325 M6 1 D5 4 TR315

#10 — 32 H3 4 TR343 M8 1.25 D5 4 TR365

1/4 20 — H3 4 TR403

1/4 20 — H5 4 TR405 M10 1.5 D6 4 TR426

1/4 — 28 H3 4 TR423 M12 1.25 D6 4 TR526

5/16 18 — H3 4 TR443 M12 1.75 D6 4 TR506

5/16 18 — H5 4 TR445 M14 1.25 D6 4 TR566

5/16 — 24 H3 4 TR463 M14 1.5 D6 4 TR556

3/8 16 — H3 4 TR483 M16 1.5 D6 4 TR616

3/8 16 — H5 4 TR485

3/8 — 24 H3 4 TR503 M18 1.5 D6 4 TR676

7/16 14 — H3 4 TR523 ▶Refer to technical data on page 520~554.

7/16 14 — H5 4 TR525

7/16 — 20 H3 4 TR543

7/16 — 20 H5 4 TR545

1/2 13 — H3 4 TR563

1/2 13 — H5 4 TR565

1/2 — 20 H3 4 TR583

1/2 — 20 H5 4 TR585

9/16 12 — H3 4 TR603

9/16 12 — H5 4 TR605

9/16 — 18 H3 4 TR623

9/16 — 18 H5 4 TR625

5/8 11 — H3 4 TR643

5/8 11 — H5 4 TR645

5/8 — 18 H3 4 TR663

5/8 — 18 H5 4 TR665

3/4 10 — H3 4 TR703

3/4 10 — H5 4 TR705

3/4 — 16 H3 4 TR723

3/4 — 16 H5 4 TR725

▶Refer to technical data on page 520~554. ▶ NEXT PAGE

◎ : Excellent ○: Good ◎ : Excellent ○: Good

P M K P M K

Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey

Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron

carbon steels Low alloyed steels Valve stainless steels stainless steels carbon steels Low alloyed steels Valve stainless steels stainless steels

~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19 ~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19

(~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220) (~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220)

◎ ◎

K N S K N S

Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718 Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718

Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium

Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286 Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286

~HRc24 (~HB250) ~HRc24 (~HB250)

◎ ◎

472 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 473