Page 514 - YG 2019

P. 514

PIPE TAPS PIPE TAPS T7L36/T6L36 SERIES

S1/S2 SERIES T7536/T6536 SERIES

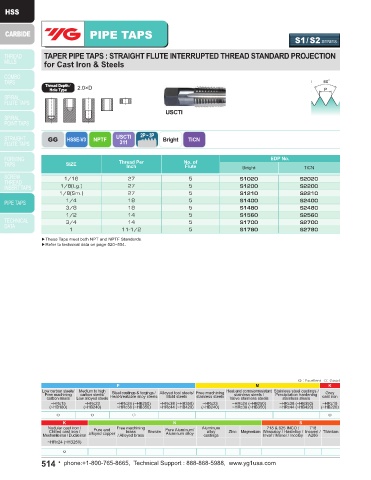

TAPER PIPE TAPS : STRAIGHT FLUTE INTERRUPTED THREAD STANDARD PROJECTION STRAIGHT PIPE TAPS for General Purpose

for Cast Iron & Steels

Thread Depth / 2.0×D Thread Depth / 2.0×D

Hole Type Hole Type

USCTI USCTI

NPS

GG HSSE-V3 NPTF USCTI Bright TiCN GS HSS NPSF USCTI 4P~5P Bright Steam

Oxide

311

311

EDP No. T7L36 / T6L36 Series (NPS)

SIZE Thread Per No. of Bright TiCN EDP No.

Inch

Flute

SIZE Thread Per No. of Steam

Flute

Inch

1/16 27 5 S1020 S2020 Bright Oxide

1/8(Lg.) 27 5 S1200 S2200 1/8 (Lg.) 27 4 T7L36200 T6L36200

1/8(Sm.) 27 5 S1210 S2210 1/8 (Sm.) 27 4 T7L36210 T6L36210

1/4 18 5 S1400 S2400 1/4 18 4 T7L36400 T6L36400

3/8 18 5 S1480 S2480 3/8 18 4 T7L36480 T6L36480

1/2 14 5 S1560 S2560 1/2 14 4 T7L36560 T6L36560

3/4 14 5 S1700 S2700 3/4 14 5 T7L36700 T6L36700

1 11-1/2 5 S1780 S2780 1 11-1/2 5 T7L36780 T6L36780

▶These Taps meet both NPT and NPTF Standards.

▶Refer to technical data on page 520~554.

T7536 / T6536 Series (NPSF)

EDP No.

SIZE Thread Per No. of Steam

Flute

Inch

Bright

Oxide

1/8 (Lg.) 27 4 T7536200 T6536200

1/8 (Sm.) 27 4 T7536210 T6536210

1/4 18 4 T7536400 T6536400

3/8 18 4 T7536480 T6536480

1/2 14 4 T7536560 T6536560

3/4 14 5 T7536700 T6536700

1 11-1/2 5 T7536780 T6536780

▶Refer to technical data on page 520~554.

◎ : Excellent ○: Good ◎ : Excellent ○: Good

P M K P M K

Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey

Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron

carbon steels Low alloyed steels Valve stainless steels stainless steels carbon steels Low alloyed steels Valve stainless steels stainless steels

~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19 ~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19

(~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220) (~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220)

◎ ◎ ○ ◎ ○ ○ ○

K N S K N S

Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718 Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718

Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium

Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286 Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286

~HRc24 (~HB250) ~HRc24 (~HB250)

◎ ○ ○

514 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 515