Page 516 - YG 2019

P. 516

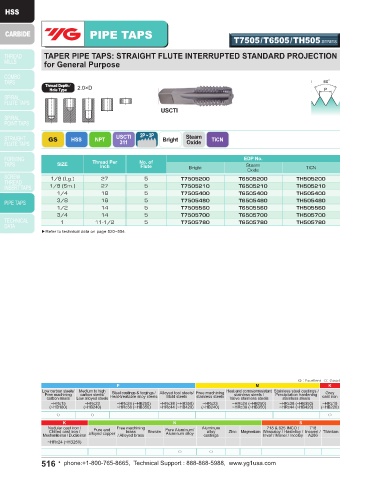

PIPE TAPS PIPE TAPS

T7505/T6505/TH505 SERIES T7546/T8546 SERIES

TAPER PIPE TAPS: STRAIGHT FLUTE INTERRUPTED STANDARD PROJECTION TAPER PIPE TAPS: STRAIGHT FLUTE STANDARD PROJECTION 6" EXTENSION

for General Purpose for General Purpose

Thread Depth / 2.0×D Thread Depth / 2.0×D

Hole Type Hole Type

USCTI USCTI

GS HSS NPT USCTI Bright Steam TiCN GS HSS NPTF USCTI Bright TiN

Oxide

311

311

EDP No. Overall Thread Shank EDP No.

SIZE Thread Per No. of Steam SIZE Threads Length Length Diameter No. of Flute

Inch

Per Inch

Flute

Bright

Oxide TiCN L Lt D Bright TiN

1/8 (Lg.) 27 5 T7505200 T6505200 TH505200 1/8 27 6.0 3/4 .4375 4 T7546200 T8546200

1/8 (Sm.) 27 5 T7505210 T6505210 TH505210 1/4 18 6.0 1-1/16 .5625 4 T7546400 T8546400

1/4 18 5 T7505400 T6505400 TH505400 3/8 18 6.0 1-1/16 .7000 4 T7546480 T8546480

3/8 18 5 T7505480 T6505480 TH505480 1/2 14 6.0 1-3/8 .6875 4 T7546560 T8546560

1/2 14 5 T7505560 T6505560 TH505560 3/4 14 6.0 1-3/8 .9063 5 T7546700 T8546700

3/4 14 5 T7505700 T6505700 TH505700 1 11-1/2 6.0 1-3/4 1.1250 5 T7546780 T8546780

1 11-1/2 5 T7505780 T6505780 TH505780 ▶Refer to technical data on page 520~554.

▶Refer to technical data on page 520~554. ▶These Taps meet both NPT and NPTF Standards.

◎ : Excellent ○: Good ◎ : Excellent ○: Good

P M K P M K

Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey

Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron

carbon steels Low alloyed steels Valve stainless steels stainless steels carbon steels Low alloyed steels Valve stainless steels stainless steels

~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19 ~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19

(~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220) (~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220)

○ ○ ○ ○ ○ ○

K N S K N S

Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718 Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718

Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium

Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286 Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286

~HRc24 (~HB250) ~HRc24 (~HB250)

○ ○ ○ ○

516 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 517