Page 633 - YG 2019

P. 633

X5070 X5070

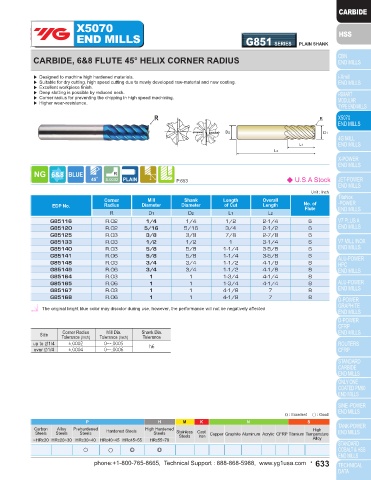

END MILLS G850 SERIES PLAIN SHANK END MILLS G851 SERIES PLAIN SHANK

CARBIDE, 4 FLUTE STUB LENGTH CORNER RADIUSwith EXTENDED NECK CARBIDE, 6&8 FLUTE 45° HELIX CORNER RADIUS

▶ Designed to machine high hardened materials. ▶ Designed to machine high hardened materials.

▶ Suitable for dry cutting, high speed cutting due to newly developed raw-material and new coating. ▶ Suitable for dry cutting, high speed cutting due to newly developed raw-material and new coating.

▶ Excellent workpiece finish. ▶ Excellent workpiece finish.

▶ Deep slotting is possible by reduced neck. ▶ Deep slotting is possible by reduced neck.

▶ Corner radius for preventing the chipping in high speed machining. ▶ Corner radius for preventing the chipping in high speed machining.

▶ Higher wear-resistance. ▶ Higher wear-resistance.

X5070 R D3 R R R X5070

END MILLS ↙ ↙ END MILLS

D2 D1

D2 D1

L1

L3 L1

L2

L2

P.653 ◆ U.S.A Stock P.653 ◆ U.S.A Stock

Unit : Inch Unit : Inch

Corner Mill Shank Length Length Overall Neck Corner Mill Shank Length Overall

EDP No. Radius Diameter Diameter of Cut Below Shank Length Diameter EDP No. Radius Diameter Diameter of Cut Length No. of

Flute

R D1 D2 L1 L3 L2 D3 R D1 D2 L1 L2

G85004 R.004 1/16 1/8 3/32 - 1-1/2 - G85116 R.02 1/4 1/4 1/2 2-1/4 6

G85008 R.004 1/8 1/4 5/32 1/4 2 .119 G85120 R.02 5/16 5/16 3/4 2-1/2 6

G85012 R.004 3/16 1/4 1/4 3/8 2 .181 G85125 R.03 3/8 3/8 7/8 2-7/8 6

G85016 R.008 1/4 1/4 5/16 9/16 2 .238 G85133 R.03 1/2 1/2 1 3-1/4 6

G85020 R.008 5/16 5/16 3/8 3/4 2-1/2 .301 G85140 R.03 5/8 5/8 1-1/4 3-5/8 6

G85024 R.008 3/8 3/8 1/2 1 3 .363 G85141 R.06 5/8 5/8 1-1/4 3-5/8 6

G85032 R.012 1/2 1/2 5/16 1-3/16 3 .488 G85148 R.03 3/4 3/4 1-1/2 4-1/8 8

G85040 R.012 5/8 5/8 3/4 1-1/2 3-1 .613 G85149 R.06 3/4 3/4 1-1/2 4-1/8 8

G85048 R.012 3/4 3/4 1 1-3/4 4 .738 G85164 R.03 1 1 1-3/4 4-1/4 8

G85165 R.06 1 1 1-3/4 4-1/4 8

The original bright blue color may discolor during use, however, the performance will not be negatively affected

G85167 R.03 1 1 4-1/8 7 8

G85168 R.06 1 1 4-1/8 7 8

The original bright blue color may discolor during use, however, the performance will not be negatively affected

Size Corner Radius Mill Dia. Shank Dia.

Tolerance (Inch) Tolerance (Inch) Tolerance

up to Ø1/4 ±.0002 0~-.0005 h6

over Ø1/4 ±.0004 0~-.0006

Size Corner Radius Mill Dia. Shank Dia.

Tolerance (Inch) Tolerance (Inch) Tolerance

up to Ø1/4 ±.0002 0~-.0005 h6

over Ø1/4 ±.0004 0~-.0006

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Steels

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ○ ◎ ◎ ○ ○ ◎ ◎

632 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 633