Page 651 - YG 2019

P. 651

X5070 X5070

END MILLS G8A39 SERIES PLAIN SHANK END MILLS RECOMMENDED CUTTING CONDITIONS

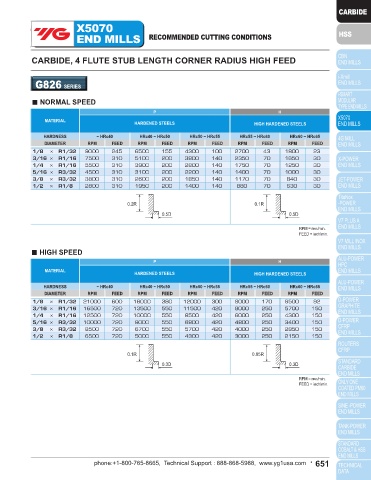

CARBIDE, 6 FLUTE 45° HELIX CORNER RADIUS with EXTENDED NECK CARBIDE, 4 FLUTE STUB LENGTH CORNER RADIUS HIGH FEED

▶ Designed to machine high hardened materials

▶ Suitable for dry cutting, high speed cutting due to newly developed raw-material and new coating.

▶ Excellent workpiece finish. G826 SERIES

▶ Deep slotting is possible by reduced neck.

▶ Corner radius for preventing the chipping in high speed machining

▶ Higher wear-resistance. ■ NORMAL SPEED

P H

X5070 R D3 R MATERIAL X5070

END MILLS ↙ HARDENED STEELS HIGH HARDENED STEELS END MILLS

D2 D1

L1 HARDNESS ~ HRc40 HRc40 ~ HRc50 HRc50 ~ HRc55 HRc55 ~ HRc60 HRc60 ~ HRc65

L3 DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

L2

1/8 × R1/32 9000 245 6500 155 4300 100 2700 43 1800 23

3/16 × R1/16 7500 310 5100 200 3800 140 2350 70 1650 30

1/4 × R1/16 5500 310 3900 200 2800 140 1750 70 1250 30

5/16 × R3/32 4500 310 3100 200 2200 140 1400 70 1000 30

P.660 ◇ Call for Availability 3/8 × R3/32 3800 310 2600 200 1850 140 1170 70 840 30

Ø6 Ø8~Ø20 1/2 × R1/8 2800 310 1950 200 1400 140 880 70 630 30

Unit : mm

Corner Mill Diameter Shank Length Length Overall Neck

EDP No. Radius Metric Inch Diameter of Cut Below Shank Length Diameter 0.2R 0.1R

R D1 D2 L1 L3 L2 D3 0.5D 0.5D

G8A39916 R0.25 6.0 .2362 6 6 14 50 5.85

G8A39060 R0.5 6.0 .2362 6 6 14 50 5.85 RPM = rev./min.

G8A39901 R0.5 6.0 .2362 6 13 - 70 - FEED = inch/min.

✽ G8A39910 R0.5 6.0 .2362 6 26 - 70 -

G8A39080 R0.5 8.0 .3150 8 8 24 60 7.7 ■ HIGH SPEED

G8A39902 R0.5 8.0 .3150 8 19 - 90 -

✽ G8A39911 R0.5 8.0 .3150 8 36 - 90 - P H

G8A39903 R0.5 10.0 .3937 10 22 - 100 - MATERIAL

G8A39100 R1.0 10.0 .3937 10 10 30 70 9.7 HARDENED STEELS HIGH HARDENED STEELS

G8A39904 R1.0 10.0 .3937 10 22 - 100 - HARDNESS ~ HRc40 HRc40 ~ HRc50 HRc50 ~ HRc55 HRc55 ~ HRc60 HRc60 ~ HRc65

✽ G8A39912 R1.0 10.0 .3937 10 46 - 100 - DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

G8A39905 R0.5 12.0 .4724 12 26 - 110 -

G8A39120 R1.0 12.0 .4724 12 12 30 75 11.7 1/8 × R1/32 21000 600 16000 380 12000 300 9000 170 6500 92

G8A39906 R1.0 12.0 .4724 12 26 - 110 - 3/16 × R1/16 16500 720 13500 550 11500 420 8000 250 5700 150

✽ G8A39913 R1.0 12.0 .4724 12 56 - 110 - 1/4 × R1/16 12500 720 10000 550 8500 420 6000 250 4300 150

G8A39160 R1.0 16.0 .6299 16 32 - 130 - 5/16 × R3/32 10000 720 8000 550 6800 420 4800 250 3400 150

G8A39907 R1.5 16.0 .6299 16 32 - 130 - 3/8 × R3/32 8500 720 6700 550 5700 420 4000 250 2850 150

✽ G8A39914 R1.5 16.0 .6299 16 66 - 130 - 1/2 × R1/8 6500 720 5000 550 4300 420 3000 250 2150 150

G8A39200 R1.0 20.0 .7874 20 38 - 140 -

G8A39908 R1.5 20.0 .7874 20 38 - 140 - 0.1R 0.05R

G8A39909 R2.0 20.0 .7874 20 38 - 140 -

✽ G8A39915 R2.0 20.0 .7874 20 76 - 140 - 0.3D 0.3D

The original bright blue color may discolor during use, however, the performance will not be negatively affected RPM = rev./min.

FEED = inch/min.

Size Corner Radius Mill Dia. Shank Dia.

Tolerance (mm) Tolerance (mm) Tolerance

up to Ø6 ±0.010 0~-0.02 h6

over Ø6 ±0.015 (✽Extra Long Type : 0~-0.03)

◎ : Excellent ◯ : Good

P H M K N S

Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ○ ◎ ◎

650 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 651