Page 923 - YG 2019

P. 923

X-POWER X-POWER

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

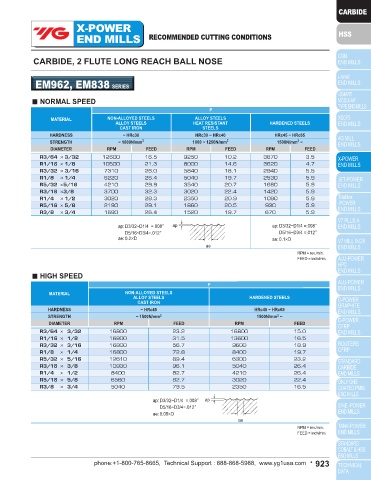

CARBIDE, 2 FLUTE MEDIUM LENGTH BALL NOSE CARBIDE, 2 FLUTE LONG REACH BALL NOSE

EM961, EM899 SERIES EM962, EM838 SERIES

■ NORMAL SPEED ■ NORMAL SPEED

P P

MATERIAL ALLOY STEELS MATERIAL NON-ALLOYED STEELS ALLOY STEELS

HEAT RESISTANT HARDENED STEELS HARDENED STEELS ALLOY STEELS HEAT RESISTANT HARDENED STEELS

STEELS CAST IRON STEELS

HARDNESS HRc30 ~ HRc40 HRc45 ~ HRc50 HRc50 ~ HRc55 HARDNESS ~ HRc30 HRc30 ~ HRc40 HRc45 ~ HRc65

2

STRENGTH 1000 ~ 1250N/mm 2 1500 ~ 1750N/mm 2 1750 ~ 2000N/mm 2 STRENGTH ~ 1000N/mm 2 1000 ~ 1250N/mm 2 1500N/mm ~

DIAMETER RPM FEED RPM FEED RPM FEED DIAMETER RPM FEED RPM FEED RPM FEED

R1/16 × 1/8 10000 18.1 12700 43.3 12300 41.3 R3/64 × 3/32 12600 16.5 9250 10.2 3870 3.5

R3/32 × 3/16 7300 22.8 9400 43.3 9050 41.3 R1/16 × 1/8 10500 21.3 8000 14.6 3620 4.7

R1/8 × 1/4 6300 24.8 8600 45.3 8250 43.3 R3/32 × 3/16 7310 26.0 5840 18.1 2940 5.5

R5/32 × 5/16 4420 26.0 7000 41.3 6700 39.4 R1/8 × 1/4 6220 26.4 5040 19.7 2530 5.9

R3/16 × 3/8 3780 28.0 6050 39.4 5800 37.8 R5/32 ×5/16 4210 29.9 3540 20.7 1680 5.9

R1/4 × 1/2 2940 26.0 5450 39.4 5200 37.8 R3/16 ×3/8 3700 32.3 3020 22.4 1420 5.9

R5/16 × 5/8 2320 26.0 4350 34.3 4150 32.7 R1/4 × 1/2 3020 28.3 2350 20.9 1090 5.9

R3/8 × 3/4 1900 25.0 3500 27.2 3300 25.6 R5/16 × 5/8 2190 29.1 1860 20.5 930 5.9

R1/2 × 1 1520 25.0 2800 27.2 2650 25.6 R3/8 × 3/4 1680 26.4 1520 19.7 670 5.9

ap: D1/8~D1/4 =.008″ ap: D1/8 = .006″ ap ap: D3/32~D1/4 =.008″ ap ap: D3/32~D1/4 =.008″

D5/16~D1 =.012″ D3/16~D5/16 = .010″ D5/16~D3/4=.012″ D5/16~D3/4 =.012″

ae: 0.2×D D3/8~D1 = .012″ ae: 0.2×D ae: 0.1×D

ae: 0.1×D ae ae

RPM = rev./min. RPM = rev./min.

FEED = inch/min. FEED = inch/min.

■ HIGH SPEED ■ HIGH SPEED

P P

MATERIAL ALLOY STEELS MATERIAL NON-ALLOYED STEELS

HEAT RESISTANT HARDENED STEELS HARDENED STEELS ALLOY STEELS HARDENED STEELS

STEELS CAST IRON

HARDNESS ~ HRc45 HRc45 ~ HRc50 HRc50 ~ HRc55 HARDNESS ~ HRc45 HRc45 ~ HRc65

2

STRENGTH 1000 ~ 1250N/mm 2 1500 ~ 1750N/mm 2 1750 ~ 2000N/mm 2 STRENGTH ~ 1500N/mm 2 1500N/mm ~

DIAMETER RPM FEED RPM FEED RPM FEED DIAMETER RPM FEED RPM FEED

R1/16 × 1/8 21000 39.4 12700 68.9 12300 65.7 R3/64 × 3/32 16800 23.2 16800 15.0

R3/32 × 3/16 21000 70.9 9400 65.0 9050 61.8 R1/16 × 1/8 16800 31.5 13600 16.5

R1/8 × 1/4 21000 90.9 8600 69.0 8250 65.7 R3/32 × 3/16 16800 56.7 9600 18.9

R5/32 × 5/16 15760 111.8 7000 61.0 6700 57.5 R1/8 × 1/4 16800 72.8 8400 19.7

R3/16 × 3/8 13660 120.1 6050 57.1 5800 53.5 R5/32 × 5/16 12610 89.4 6300 23.2

R1/4 × 1/2 10500 103.5 5450 55.9 5200 52.4 R3/16 × 3/8 10930 96.1 5040 26.4

R5/16 × 5/8 8200 103.5 4350 48.4 4150 44.5 R1/4 × 1/2 8400 82.7 4210 26.4

R3/8 × 3/4 6300 99.2 3500 39.4 3300 35.4 R5/16 × 5/8 6560 82.7 3020 22.4

R1/2 × 1 5040 99.2 2800 39.4 2650 35.4 R3/8 × 3/4 5040 79.5 2350 16.5

ap: D1/8~D1/4 =.008 ap: D1/8 = .006″ ap ap: D3/32~D1/4 =.008″ ap

D5/16~D1 =.012 D3/16~D5/16 = .010″ D5/16~D3/4=.012″

ae: 0.05×D D3/8~D1 = .012″ ae: 0.05×D

ae: 0.05×D ae ae

RPM = rev./min. RPM = rev./min.

FEED = inch/min. FEED = inch/min.

922 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 923