Page 918 - YG 2019

P. 918

X-POWER X-POWER

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

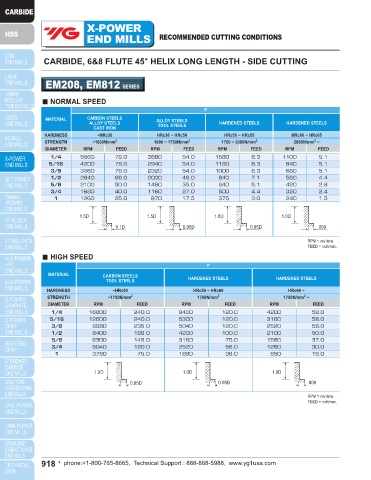

CARBIDE, 6&8 FLUTE 45° HELIX LONG LENGTH - SIDE CUTTING CARBIDE, 6&8 FLUTE 45° HELIX CORNER RADIUS - SIDE CUTTING

EM208, EM812 SERIES EM668, EM835 SERIES

■ NORMAL SPEED ■ HIGH SPEED

P P

MATERIAL CARBON STEELS ALLOY STEELS MATERIAL CARBON STEELS ALLOY STEELS

ALLOY STEELS TOOL STEELS HARDENED STEELS HARDENED STEELS ALLOY STEELS TOOL STEELS HARDENED STEELS

CAST IRON CAST IRON

HARDNESS ~HRc30 HRc30 ~ HRc50 HRc50 ~ HRc55 HRc60 ~ HRc65 HARDNESS ~ HRc50 HRc50 ~ HRc60 HRc60 ~ HRc65

2

2

STRENGTH ~1000N/mm 2 1000 ~ 1750N/mm 2 1750 ~ 2080N/mm 2 2080N/mm ~ STRENGTH ~ 1750N/mm 2 1750 ~ 2080N/mm 2 2080N/mm ~

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED DIAMETER RPM FEED RPM FEED RPM FEED

1/4 5560 79.0 3880 54.0 1580 8.3 1100 5.1 1/4 16800 240.0 8400 120.0 4200 58.0

5/16 4200 79.0 2940 54.0 1160 8.3 840 5.1 5/16 12600 240.0 6300 120.0 3200 58.0

3/8 3360 79.0 2320 54.0 1000 8.3 680 5.1 3/8 10000 235.0 5000 120.0 2500 58.0

1/2 2840 66.0 2000 46.0 840 7.1 560 4.4 1/2 8400 200.0 4200 100.0 2100 50.0

5/8 2100 50.0 1480 35.0 640 5.1 420 2.8 5/8 6300 150.0 3150 75.0 1600 37.0

3/4 1680 40.0 1160 27.0 500 4.4 320 2.4 3/4 5000 120.0 2500 58.0 1260 30.0

1 1260 25.0 870 17.5 375 3.0 240 1.5

1.5D 1.0D 1.0D

1.5D 1.5D 1.0D 1.0D

0.05D 0.05D .008

0.1D 0.05D 0.05D .008

RPM = rev./min.

RPM = rev./min. FEED = inch/min.

FEED = inch/min.

■ HIGH SPEED

P CARBIDE, 6&8 FLUTE 45° HELIX EXTRA LONG LENGTH - SIDE CUTTING

MATERIAL CARBON STEELS

TOOL STEELS HARDENED STEELS HARDENED STEELS

HARDNESS ~HRc50 HRc50 ~ HRc60 HRc60 ~

2

STRENGTH ~1750N/mm 2 1750N/mm 2 1750N/mm ~ EM218, EM812, EM834 SERIES

DIAMETER RPM FEED RPM FEED RPM FEED P

1/4 16800 240.0 8400 120.0 4200 58.0 MATERIAL NON-ALLOYED STEELS ALLOY STEELS

5/16 12600 240.0 6300 120.0 3160 58.0 ALLOY STEELS HEAT RESISTANT HARDENED STEELS HARDENED STEELS

STEELS

3/8 9980 235.0 5040 120.0 2520 58.0 HARDNESS CAST IRON HRc40 ~ HRc50 HRc50 ~ HRc60 HRc60 ~ HRc65

~HRc40

1/2 8400 199.0 4200 100.0 2100 50.0 2 2 2 2

5/8 6300 149.0 3160 75.0 1580 37.0 STRENGTH ~1250N/mm 1250 ~ 1750N/mm 1750 ~ 2080N/mm 2080N/mm ~

3/4 5040 120.0 2520 58.0 1260 30.0 DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED

1 3790 75.0 1890 38.0 950 19.0 1/4 2230 19.0 1670 14.0 1390 10.0 1110 8.0

5/16 1670 18.0 1250 13.0 1050 9.5 840 7.0

3/8 1330 17.0 1000 12.0 840 9.0 680 6.3

1.5D 1.0D 1.0D 1/2 1110 16.0 840 11.0 690 8.5 560 6.0

5/8 840 13.0 630 9.0 530 6.5 420 5.0

0.05D 0.05D .008

3/4 670 11.0 500 8.0 420 6.0 320 4.7

1 540 9.5 400 6.5 340 5.0 270 3.7

RPM = rev./min.

FEED = inch/min.

3D 3D

0.01D 0.005D

RPM = rev./min.

FEED = inch/min.

918 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 919