Page 976 - YG 2019

P. 976

TitaNox-POWER

END MILLS RECOMMENDED CUTTING CONDITIONS

CARBIDE

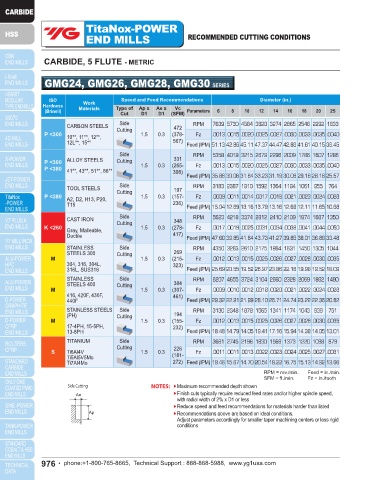

CARBIDE, 5 FLUTE - METRIC Being the best through innovation

GMG24, GMG26, GMG28, GMG30 SERIES

ISO Speed and Feed Recommendations Diameter (in.)

Hardness Work Type of Ap x Ae x Vc

(Brinell) Materials Cut D1 D1 (SFM) Parameters 6 8 10 12 14 16 18 20 25

Side RPM 7639 5730 4584 3820 3274 2865 2546 2292 1833

CARBON STEELS Cutting 472

P <300 10**, 11**, 12**, 1.5 0.3 (378- Fz .0013 .0015 .0020 .0025 .0027 .0030 .0033 .0035 .0040

12L**, 15** 567) Feed (IPM) 51.13 42.86 45.11 47.37 44.47 42.86 41.61 40.15 36.45

Side RPM 5358 4019 3215 2679 2296 2009 1786 1607 1286

P <300 ALLOY STEELS Cutting 331

P <380 41**, 43**, 51**, 86** 1.5 0.3 (265- Fz .0013 .0015 .0020 .0025 .0027 .0030 .0033 .0035 .0040

398)

Feed (IPM) 35.86 30.06 31.64 33.23 31.19 30.06 29.18 28.16 25.57

Side

TOOL STEELS Cutting 197 RPM 3183 2387 1910 1592 1364 1194 1061 955 764

P <380 A2, D2, H13, P20, 1.5 0.3 (157- Fz .0009 .0011 .0014 .0017 .0019 .0021 .0023 .0024 .0028

T15 236) Feed (IPM) 15.04 12.69 13.16 13.79 13.16 12.69 12.11 11.65 10.68

Side

CAST IRON Cutting 348 RPM 5623 4218 3374 2812 2410 2109 1874 1687 1350

K <260 Gray, Malleable, 1.5 0.3 (278- Fz .0017 .0019 .0025 .0031 .0034 .0038 .0041 .0044 .0050

Ductile 417) Feed (IPM) 47.60 39.85 41.84 43.73 41.27 39.85 38.01 36.86 33.48

STAINLESS Side RPM 4350 3263 2610 2175 1864 1631 1450 1305 1044

STEELS 300 Cutting 269

M 1.5 0.3 (215- Fz .0012 .0013 .0015 .0025 .0026 .0027 .0028 .0030 .0035

304, 316, 304L, 323)

316L, SUS316 Feed (IPM) 25.69 20.55 19.52 26.97 23.86 22.16 19.98 19.52 18.09

STAINLESS Side RPM 6207 4655 3724 3104 2660 2328 2069 1862 1490

STEELS 400 Cutting 384

M 1.5 0.3 (307- Fz .0009 .0010 .0012 .0018 .0020 .0021 .0022 .0024 .0028

416, 420F, 430F, 461)

440F Feed (IPM) 29.32 22.91 21.99 28.10 26.71 24.74 23.22 22.36 20.82

STAINLESS STEELS Side RPM 3130 2348 1878 1565 1341 1174 1043 939 751

(PH) Cutting 194

M 1.5 0.3 (155- Fz .0012 .0013 .0015 .0025 .0026 .0027 .0028 .0030 .0035

17-4PH, 15-5PH, 232)

13-8PH Feed (IPM) 18.48 14.79 14.05 19.41 17.16 15.94 14.38 14.05 13.01

TITANIUM Side RPM 3661 2745 2196 1830 1569 1373 1220 1098 879

Cutting 226

S Ti6Al4V 1.5 0.3 Fz .0011 .0011 .0013 .0022 .0023 .0024 .0025 .0027 .0031

Ti5Al5V5Mo (181- V7 PLUS A

Ti7Al4Mo 272) Feed (IPM) 19.46 15.67 14.70 20.54 18.22 16.75 15.13 14.92 13.66

RPM = rev./min. Feed = in./min.

SFM = ft./min. Fz = in./tooth

Side Cutting NOTES: Maximum recommended depth shown

Finish cuts typically require reduced feed rates and/or higher spindle speed, END MILLS

Ae

with radial width of 2% x D1 or less

Reduce speed and feed recommendations for materials harder than listed

Ap Recommendations above are based on ideal conditions.

Adjust parameters accordingly for smaller taper machining centers or less rigid

conditions

- Silent Cutting of Steels up to HRc40

Designed as Unequal Leads.

976 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com