Page 41 - test2

P. 41

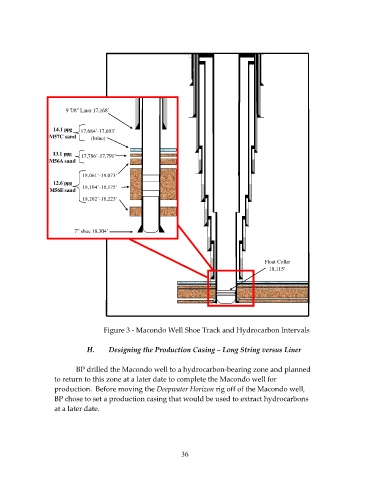

ML @ 5067' MD/TVD

36" @ 5,321' MD/TVD (254' bml)

9 7/8” Liner 17,168’

28" @ 6217' MD/TVD (1150' bml)

7,567' MD - Bot of 5-1/2" 21.9 ppf S-135 (3450' of pipe)

14.1 ppg 17,684’-17,693’

M57C sand (brine)

22" @ 7937' MD/TVD (2891' bml)

13.1 ppg 17,786’-17,791’

M56A sand

8,367' MD (3-1/2" - 800' pipe)

18" @ 8969' MD/TVD (3902' bml)

18,061’-18,073’

12.6 ppg

M56E sand 18,104’-18,175’

18,202’-18,223’ 16" @ 11,585 MD / TVD (6518' bml)

XOVER 12,487.64'

13-5/8" @ 13,145' MD / 13,133' TVD

7” shoe 18,304’

11-7/8" Liner @ 15,103' MD / 15,092' TVD

Float Collar

18,115’

9-7/8" Liner @ 17,168' MD / 17,157' TVD

TD @ 18,360' MD / 7" Shoe @ 18,303.92' MD

Figure 3 ‐ Macondo Well Shoe Track and Hydrocarbon Intervals

H. Designing the Production Casing – Long String versus Liner

BP drilled the Macondo well to a hydrocarbon‐bearing zone and planned

to return to this zone at a later date to complete the Macondo well for

production. Before moving the Deepwater Horizon rig off of the Macondo well,

BP chose to set a production casing that would be used to extract hydrocarbons

at a later date.

36