Page 236 - Robot Design Handbook ROBOCON Malaysia 2019

P. 236

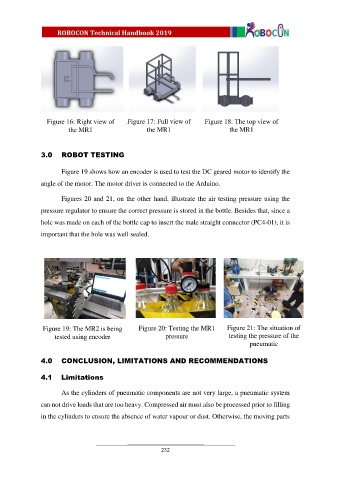

Figure 16: Right view of Figure 17: Full view of Figure 18: The top view of

the MR1 the MR1 the MR1

3.0 ROBOT TESTING

Figure 19 shows how an encoder is used to test the DC geared motor to identify the

angle of the motor. The motor driver is connected to the Arduino.

Figures 20 and 21, on the other hand, illustrate the air testing pressure using the

pressure regulator to ensure the correct pressure is stored in the bottle. Besides that, since a

hole was made on each of the bottle cap to insert the male straight connector (PC4-01), it is

important that the hole was well sealed.

. Figure 19: The MR2 is being Figure 20: Testing the MR1 Figure 21: The situation of

tested using encoder pressure testing the pressure of the

pneumatic

4.0 CONCLUSION, LIMITATIONS AND RECOMMENDATIONS

4.1 Limitations

As the cylinders of pneumatic components are not very large, a pneumatic system

can not drive loads that are too heavy. Compressed air must also be processed prior to filling

in the cylinders to ensure the absence of water vapour or dust. Otherwise, the moving parts

232