Page 83 - 100% Biker (January 2020)

P. 83

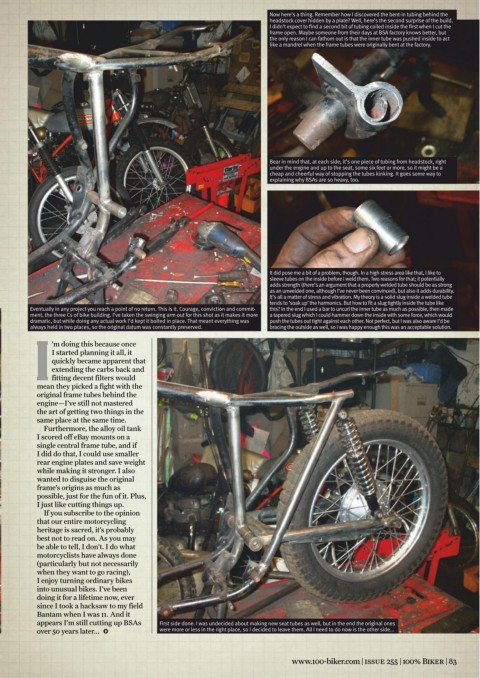

Now here’s a thing. Remember how I discovered the bent-in tubing behind the

headstock cover hidden by a plate? Well, here’s the second surprise of the build.

I didn’t expect to find a second bit of tubing coiled inside the first when I cut the

frame open. Maybe someone from their days at BSA factory knows better, but

the only reason I can fathom out is that the inner tube was pushed inside to act

like a mandrel when the frame tubes were originally bent at the factory.

Bear in mind that, at each side, it’s one piece of tubing from headstock, right

under the engine and up to the seat, some six feet or more, so it might be a

cheap and cheerful way of stopping the tubes kinking. It goes some way to

explaining why BSAs are so heavy, too.

It did pose me a bit of a problem, though. In a high stress area like that, I like to

sleeve tubes on the inside before I weld them. Two reasons for that; it potentially

adds strength (there’s an argument that a properly welded tube should be as strong

as an unwelded one, although I’ve never been convinced), but also it adds durability.

It’s all a matter of stress and vibration. My theory is a solid slug inside a welded tube

tends to ‘soak up’ the harmonics. But how to fit a slug tightly inside the tube like

Eventually in any project you reach a point of no return. This is it. Courage, conviction and commit- this? In the end I used a bar to uncurl the inner tube as much as possible, then made

ment, the three Cs of bike building. I’ve taken the swinging arm out for this shot as it makes it more a tapered slug which I could hammer down the inside with some force, which would

dramatic, but while doing any actual work I’d kept it bolted in place. That meant everything was push the tubes out tight against each other. Not perfect, but I was also aware I’d be

always held in two places, so the original datum was constantly preserved. bracing the outside as well, so I was happy enough this was an acceptable solution.

’m doing this because once

I started planning it all, it

quickly became apparent that

extending the carbs back and

I fitting decent filters would

mean they picked a fight with the

original frame tubes behind the

engine—I’ve still not mastered

the art of getting two things in the

same place at the same time.

Furthermore, the alloy oil tank

I scored off eBay mounts on a

single central frame tube, and if

I did do that, I could use smaller

rear engine plates and save weight

while making it stronger. I also

wanted to disguise the original

frame’s origins as much as

possible, just for the fun of it. Plus,

I just like cutting things up.

If you subscribe to the opinion

that our entire motorcycling

heritage is sacred, it’s probably

best not to read on. As you may

be able to tell, I don’t. I do what

motorcyclists have always done

(particularly but not necessarily

when they want to go racing),

I enjoy turning ordinary bikes

into unusual bikes. I’ve been

doing it for a lifetime now, ever

since I took a hacksaw to my field

Bantam when I was 11. And it

appears I’m still cutting up BSAs First side done. I was undecided about making new seat tubes as well, but in the end the original ones

over 50 years later... were more or less in the right place, so I decided to leave them. All I need to do now is the other side...

www.100-biker.com | issue 255 | 100% Biker | 83