Page 84 - 100% Biker (January 2020)

P. 84

BUILD FEATURE PROJECT FLATTRACK

Because the original frame has the two wide spaced tubes

running down behind the engine, the cross-tube has to be

set high to clear the chain, which in turn means elongated

rear engine plates. Hence BSA had to make them out of steel

plate nearly a quarter inch thick. With a central tube, the new

plates can be much smaller and hence thinner. I did ponder

on 6mm Dural, but all I could find in alloy was H1050. It would

probably have been alright, but A65s do tend to vibrate, and

the front and underside engine locations aren’t brilliant, being

long single bolts through the cases, so I wanted the back to

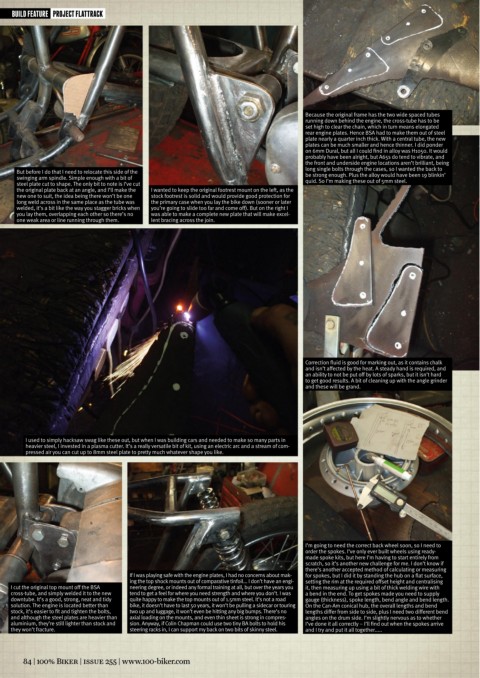

But before I do that I need to relocate this side of the be strong enough. Plus the alloy would have been 19 blinkin’

swinging arm spindle. Simple enough with a bit of quid. So I’m making these out of 5mm steel.

steel plate cut to shape. The only bit to note is I’ve cut

the original plate back at an angle, and I’ll make the I wanted to keep the original footrest mount on the left, as the

new one to suit, the idea being there won’t be one stock footrest is solid and would provide good protection for

long weld across in the same place as the tube was the primary case when you lay the bike down (sooner or later

welded, it’s a bit like the way you stagger bricks when you’re going to slide too far and come off). But on the right I

you lay them, overlapping each other so there’s no was able to make a complete new plate that will make excel-

one weak area or line running through them. lent bracing across the join.

Correction fluid is good for marking out, as it contains chalk

and isn’t affected by the heat. A steady hand is required, and

an ability to not be put off by lots of sparks, but it isn’t hard

to get good results. A bit of cleaning up with the angle grinder

and these will be grand.

I used to simply hacksaw swag like these out, but when I was building cars and needed to make so many parts in

heavier steel, I invested in a plasma cutter. It’s a really versatile bit of kit, using an electric arc and a stream of com-

pressed air you can cut up to 8mm steel plate to pretty much whatever shape you like.

I’m going to need the correct back wheel soon, so I need to

order the spokes. I’ve only ever built wheels using ready-

made spoke kits, but here I’m having to start entirely from

scratch, so it’s another new challenge for me. I don’t know if

there’s another accepted method of calculating or measuring

If I was playing safe with the engine plates, I had no concerns about mak- for spokes, but I did it by standing the hub on a flat surface,

ing the top shock mounts out of comparative tinfoil... I don’t have an engi- setting the rim at the required offset height and centralising

I cut the original top mount off the BSA neering degree, or indeed any formal training at all, but over the years you it, then measuring up using a bit of thick welding wire with

cross-tube, and simply welded it to the new tend to get a feel for where you need strength and where you don’t. I was a bend in the end. To get spokes made you need to supply

downtube. It’s a good, strong, neat and tidy quite happy to make the top mounts out of 1.5mm steel. It’s not a road gauge (thickness), spoke length, bend angle and bend length.

solution. The engine is located better than bike, it doesn’t have to last 50 years, it won’t be pulling a sidecar or touring On the Can-Am conical hub, the overall lengths and bend

stock, it’s easier to fit and tighten the bolts, two up and luggage, it won’t even be hitting any big bumps. There’s no lengths differ from side to side, plus I need two different bend

and although the steel plates are heavier than axial loading on the mounts, and even thin sheet is strong in compres- angles on the drum side. I’m slightly nervous as to whether

aluminium, they’re still lighter than stock and sion. Anyway, if Colin Chapman could use two tiny BA bolts to hold his I’ve done it all correctly – I’ll find out when the spokes arrive

they won’t fracture. steering racks in, I can support my back on two bits of skinny steel. and I try and put it all together.....

84 | 100% Biker | issue 255 | www.100-biker.com