Page 340 - (DK) The Ultimate Visual Dictionary 2nd Ed.

P. 340

RAIL AND ROAD

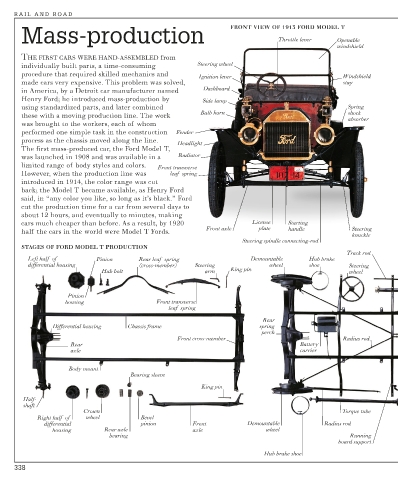

Mass-production FRONT VIEW OF 1913 FORD MODEL T

Throttle lever

Openable

windshield

THE FIRST CARS WERE HAND-ASSEMBLED from

individually built parts, a time-consuming Steering wheel

procedure that required skilled mechanics and Ignition lever Windshield

made cars very expensive. This problem was solved, stay

in America, by a Detroit car manufacturer named Dashboard

Henry Ford; he introduced mass-production by Side lamp

using standardized parts, and later combined Spring

Bulb horn shock

these with a moving production line. The work

absorber

was brought to the workers, each of whom

performed one simple task in the construction Fender

process as the chassis moved along the line.

Headlight

The first mass-produced car, the Ford Model T,

was launched in 1908 and was available in a Radiator

limited range of body styles and colors. Front transverse

However, when the production line was leaf spring

introduced in 1914, the color range was cut

back; the Model T became available, as Henry Ford

said, in “any color you like, so long as it’s black.” Ford

cut the production time for a car from several days to

about 12 hours, and eventually to minutes, making

cars much cheaper than before. As a result, by 1920 License Starting

Front axle plate handle Steering

half the cars in the world were Model T Fords.

knuckle

Steering spindle connecting-rod

STAGES OF FORD MODEL T PRODUCTION

Track rod

Left half of Pinion Rear leaf spring Demountable Hub brake

differential housing (cross-member) Steering wheel shoe Steering

Hub bolt arm King pin wheel

Pinion

housing Front transverse

leaf spring

Rear

Differential housing Chassis frame spring

perch

Front cross-member Radius rod

Rear Battery

axle carrier

Body mount

Bearing sleeve

King pin

Half-

shaft

Crown Torque tube

Right half of wheel Bevel

differential pinion Front Demountable Radius rod

housing Rear axle axle wheel

bearing Running

board support

Hub brake shoe

338