Page 91 - BE Mech Curriculum and Syllabus - R2017 - REC

P. 91

Department of MECH | REC

REFERENCES:

1. Patankar, S.V. "Numerical Heat Transfer and Fluid Flow", Hemisphere Publishing Corporation,

2004.

2. Chung, T.J. "Computational Fluid Dynamics", Cambridge University, Press, 2002.

3. Ghoshdastidar P.S., "Heat Transfer", Oxford University Press, 2005

4. Muralidhar, K., and Sundararajan, T., "Computational Fluid Flow and Heat Transfer", Narosa

Publishing House, New Delhi, 1995.

5. ProdipNiyogi, Chakrabarty, S.K., Laha, M.K. "Introduction to Computational Fluid Dynamics",

Pearson Education, 2005.

6. Anil W. Date "Introduction to Computational Fluid Dynamics" Cambridge University Press, 2005.

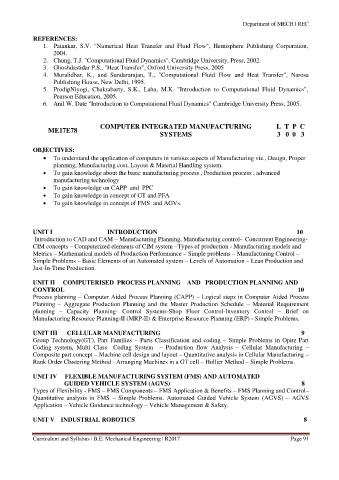

COMPUTER INTEGRATED MANUFACTURING L T P C

ME17E78

SYSTEMS 3 0 0 3

OBJECTIVES:

To understand the application of computers in various aspects of Manufacturing viz., Design, Proper

planning, Manufacturing cost, Layout & Material Handling system.

To gain knowledge about the basic manufacturing process , Production process , advanced

manufacturing technology

To gain knowledge on CAPP and PPC

To gain knowledge in concept of GT and PFA

To gain knowledge in concept of FMS and AGVs.

UNIT I INTRODUCTION 10

Introduction to CAD and CAM – Manufacturing Planning, Manufacturing control- Concurrent Engineering-

CIM concepts – Computerized elements of CIM system –Types of production - Manufacturing models and

Metrics – Mathematical models of Production Performance – Simple problems – Manufacturing Control –

Simple Problems – Basic Elements of an Automated system – Levels of Automation – Lean Production and

Just-In-Time Production.

UNIT II COMPUTERISED PROCESS PLANNING AND PRODUCTION PLANNING AND

CONTROL 10

Process planning – Computer Aided Process Planning (CAPP) – Logical steps in Computer Aided Process

Planning – Aggregate Production Planning and the Master Production Schedule – Material Requirement

planning – Capacity Planning- Control Systems-Shop Floor Control-Inventory Control – Brief on

Manufacturing Resource Planning-II (MRP-II) & Enterprise Resource Planning (ERP) - Simple Problems.

UNIT III CELLULAR MANUFACTURING 9

Group Technology(GT), Part Families – Parts Classification and coding – Simple Problems in Opitz Part

Coding system, Multi Class Coding System – Production flow Analysis – Cellular Manufacturing –

Composite part concept – Machine cell design and layout – Quantitative analysis in Cellular Manufacturing –

Rank Order Clustering Method - Arranging Machines in a GT cell – Hollier Method – Simple Problems.

UNIT IV FLEXIBLE MANUFACTURING SYSTEM (FMS) AND AUTOMATED

GUIDED VEHICLE SYSTEM (AGVS) 8

Types of Flexibility - FMS – FMS Components – FMS Application & Benefits – FMS Planning and Control–

Quantitative analysis in FMS – Simple Problems. Automated Guided Vehicle System (AGVS) – AGVS

Application – Vehicle Guidance technology – Vehicle Management & Safety.

UNIT V INDUSTRIAL ROBOTICS 8

Curriculum and Syllabus | B.E. Mechanical Engineering | R2017 Page 91