Page 89 - REC :: All Dept Open Electives

P. 89

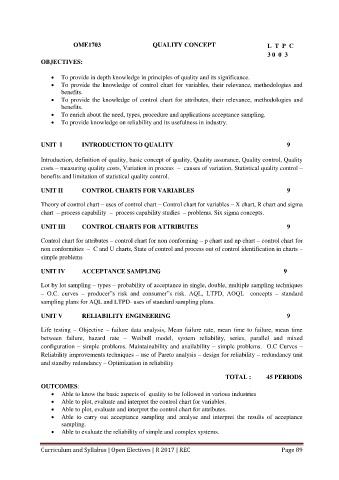

OME1703 QUALITY CONCEPT L T P C

3 0 0 3

OBJECTIVES:

To provide in depth knowledge in principles of quality and its significance.

To provide the knowledge of control chart for variables, their relevance, methodologies and

benefits.

To provide the knowledge of control chart for attributes, their relevance, methodologies and

benefits.

To enrich about the need, types, procedure and applications acceptance sampling.

To provide knowledge on reliability and its usefulness in industry.

UNIT I INTRODUCTION TO QUALITY 9

Introduction, definition of quality, basic concept of quality, Quality assurance, Quality control, Quality

costs – measuring quality costs, Variation in process – causes of variation, Statistical quality control –

benefits and limitation of statistical quality control.

UNIT II CONTROL CHARTS FOR VARIABLES 9

Theory of control chart – uses of control chart – Control chart for variables – X chart, R chart and sigma

chart – process capability – process capability studies – problems. Six sigma concepts.

UNIT III CONTROL CHARTS FOR ATTRIBUTES 9

Control chart for attributes – control chart for non conforming – p chart and np chart – control chart for

non conformities – C and U charts, State of control and process out of control identification in charts –

simple problems

UNIT IV ACCEPTANCE SAMPLING 9

Lot by lot sampling – types – probability of acceptance in single, double, multiple sampling techniques

– O.C. curves – producer‖s risk and consumer‖s risk. AQL, LTPD, AOQL concepts – standard

sampling plans for AQL and LTPD- uses of standard sampling plans.

UNIT V RELIABILITY ENGINEERING 9

Life testing – Objective – failure data analysis, Mean failure rate, mean time to failure, mean time

between failure, hazard rate – Weibull model, system reliability, series, parallel and mixed

configuration – simple problems. Maintainability and availability – simple problems. O.C Curves –

Reliability improvements techniques – use of Pareto analysis – design for reliability – redundancy unit

and standby redundancy – Optimization in reliability

TOTAL : 45 PERIODS

OUTCOMES:

Able to know the basic aspects of quality to be followed in various industries

Able to plot, evaluate and interpret the control chart for variables.

Able to plot, evaluate and interpret the control chart for attributes.

Able to carry out acceptance sampling and analyse and interpret the results of acceptance

sampling.

Able to evaluate the reliability of simple and complex systems.

Curriculum and Syllabus | Open Electives | R 2017 | REC Page 89