Page 71 - pd297-Sept21-mag-web

P. 71

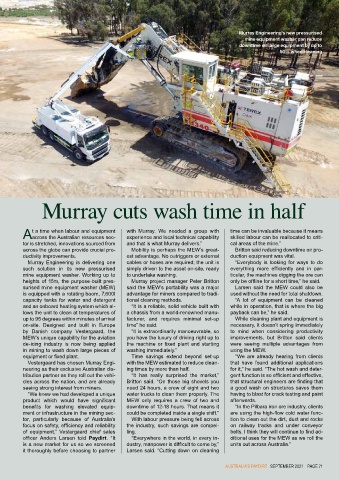

Murray Engineering’s new pressurised

mine equipment washer can reduce

downtime on large equipment by up to

50% when cleaning

Murray cuts wash time in half

t a time when labour and equipment with Murray. We needed a group with time can be invaluable because it means

Aacross the Australian resources sec- experience and local technical capability skilled labour can be reallocated to criti-

tor is stretched, innovations sourced from and that is what Murray delivers.” cal areas of the mine.”

across the globe can provide crucial pro- Mobility is perhaps the MEW’s great- Britton said reducing downtime on pro-

ductivity improvements. est advantage. No outriggers or external duction equipment was vital.

Murray Engineering is delivering one cables or hoses are required; the unit is “Everybody is looking for ways to do

such solution in its new pressurised simply driven to the asset on-site, ready everything more efficiently and in par-

mine equipment washer. Working up to to undertake washing. ticular, the machines digging the ore can

heights of 15m, the purpose-built pres- Murray project manager Peter Britton only be offline for a short time,” he said.

surised mine equipment washer (MEW) said the MEW’s portability was a major Larsen said the MEW could also be

is equipped with a rotating boom, 7,600l advantage for miners compared to tradi- used without the need for total shutdown.

capacity tanks for water and detergent tional cleaning methods. “A lot of equipment can be cleaned

and an onboard heating system which al- “It is a reliable, solid vehicle built with while in operation, that is where the big

lows the unit to clean at temperatures of a chassis from a world-renowned manu- payback can be,” he said.

up to 95 degrees within minutes of arrival facturer, and requires minimal set-up While cleaning plant and equipment is

on-site. Designed and built in Europe time” he said. necessary, it doesn’t spring immediately

by Danish company Vestergaard, the “It is extraordinarily manoeuvrable, so to mind when considering productivity

MEW’s unique capability for the aviation you have the luxury of driving right up to improvements, but Britton said clients

de-icing industry is now being applied the machine or fixed plant and starting were seeing multiple advantages from

in mining to wash down large pieces of washing immediately.” using the MEW.

equipment or fixed plant. Time savings extend beyond set-up “We are already hearing from clients

Vestergaard has chosen Murray Engi- with the MEW estimated to reduce clean- that have found additional applications

neering as their exclusive Australian dis- ing times by more than half. for it,” he said. “The hot wash and deter-

tribution partner as they roll out the vehi- “It has really surprised the market,” gent function is so efficient and effective,

cles across the nation, and are already Britton said. “On those big shovels you that structural engineers are finding that

seeing strong interest from miners. need 24 hours, a crew of eight and two a good wash on structures saves them

“We knew we had developed a unique water trucks to clean them properly. The having to blast for crack testing and paint

product which would have significant MEW only requires a crew of two and afterwards.

benefits for washing elevated equip- downtime of 12-18 hours. That means it “In the Pilbara iron ore industry, clients

ment or infrastructure in the mining sec- could be completed inside a single shift.” are using the high-flow cold water func-

tor, particularly because of Australia’s With labour pressure being felt across tion to clean out the dirt, dust and rocks

focus on safety, efficiency and reliability the industry, such savings are compel- on railway tracks and under conveyor

of equipment,” Vestergaard chief sales ling. belts. I think they will continue to find ad-

officer Anders Larsen told Paydirt. “It “Everywhere in the world, in every in- ditional uses for the MEW as we roll the

is a new market for us so we screened dustry, manpower is difficult to come by,” units out across Australia.”

it thoroughly before choosing to partner Larsen said. “Cutting down on cleaning

aUSTRaLIa’S PaYDIRT SePTeMBeR 2021 Page 71