Page 388 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 388

The City & Guilds Textbook: Plumbing Book 1

Unvented hot water storage systems and pipework arrangements

Many installers claim that an unvented hot water storage system is the best

type of system for any domestic situation, but this is far from the case. There

are many factors that must be considered before this arrangement is installed

into a property:

● Available pressure and flow rate – this is probably the most important

factor, simply because poor pressure and flow rate will affect the operating

performance of the installation. Pressure and flow rate readings should be

taken at peak times to ensure adequate water supply before recommending

this type of system.

● The route of the discharge pipework, termination and discharge pipework size.

● The type of terminal fittings to be used. This is especially important when

retro-fitting unvented installations onto existing hot water systems as the

existing taps etc. may not be suitable.

● Cost – unvented systems tend to be very expensive.

The types of unvented hot water storage cylinder

There are two types of unvented hot water storage cylinder; both are

manufactured to BS EN 12897:2006 – Specification for Indirectly Heated

Unvented (Closed) Storage Water Heaters and Available as Direct Fired/

Heated or Indirectly Heated Vessels:

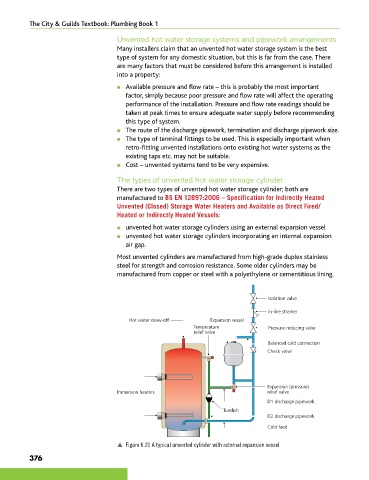

● unvented hot water storage cylinders using an external expansion vessel

● unvented hot water storage cylinders incorporating an internal expansion

air gap.

Most unvented cylinders are manufactured from high-grade duplex stainless

steel for strength and corrosion resistance. Some older cylinders may be

manufactured from copper or steel with a polyethylene or cementitious lining.

Isolation valve

In-line strainer

Hot water draw-off Expansion vessel

Temperature Pressure reducing valve

relief valve

Balanced cold connection

Check valve

Expansion (pressure)

Immersion heaters relief valve

D1 discharge pipework

Tundish

D2 discharge pipework

Cold feed

p Figure 6.21 A typical unvented cylinder with external expansion vessel

376

9781510416482.indb 376 29/03/19 9:01 PM