Page 389 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 389

Chapter 6 Hot water systems

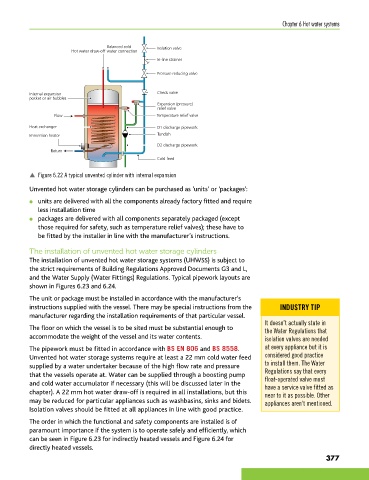

Balanced cold Isolation valve

Hot water draw-off water connection

In-line strainer

Pressure reducing valve

Internal expansion Check valve

pocket or air bubbles

Expansion (pressure)

relief valve

Flow Temperature relief valve

Heat exchanger D1 discharge pipework

Immersion heater Tundish

D2 discharge pipework

Return

Cold feed

p Figure 6.22 A typical unvented cylinder with internal expansion

Unvented hot water storage cylinders can be purchased as ‘units’ or ‘packages’:

● units are delivered with all the components already factory fitted and require

less installation time

● packages are delivered with all components separately packaged (except

those required for safety, such as temperature relief valves); these have to

be fitted by the installer in line with the manufacturer’s instructions.

The installation of unvented hot water storage cylinders

The installation of unvented hot water storage systems (UHWSS) is subject to

the strict requirements of Building Regulations Approved Documents G3 and L,

and the Water Supply (Water Fittings) Regulations. Typical pipework layouts are

shown in Figures 6.23 and 6.24.

The unit or package must be installed in accordance with the manufacturer’s

instructions supplied with the vessel. There may be special instructions from the INDUSTRY TIP

manufacturer regarding the installation requirements of that particular vessel.

It doesn’t actually state in

The floor on which the vessel is to be sited must be substantial enough to the Water Regulations that

accommodate the weight of the vessel and its water contents. isolation valves are needed

The pipework must be fitted in accordance with BS EN 806 and BS 8558. at every appliance but it is

Unvented hot water storage systems require at least a 22 mm cold water feed considered good practice

supplied by a water undertaker because of the high flow rate and pressure to install them. The Water

that the vessels operate at. Water can be supplied through a boosting pump Regulations say that every

float-operated valve must

and cold water accumulator if necessary (this will be discussed later in the have a service valve fitted as

chapter). A 22 mm hot water draw-off is required in all installations, but this near to it as possible. Other

may be reduced for particular appliances such as washbasins, sinks and bidets. appliances aren’t mentioned.

Isolation valves should be fitted at all appliances in line with good practice.

The order in which the functional and safety components are installed is of

paramount importance if the system is to operate safely and efficiently, which

can be seen in Figure 6.23 for indirectly heated vessels and Figure 6.24 for

directly heated vessels.

377

9781510416482.indb 377 29/03/19 9:01 PM