Page 452 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 452

The City & Guilds Textbook: Plumbing Book 1

the same temperature and this negates the need to increase heat emitter size

due to temperature loss. The temperature difference across each flow and

return is usually 12°C to 15°C with a flow temperature of around 80°C.

Table 7.1 Advantages and disadvantages of the one-pipe system

Advantages Disadvantages

Cheap to install because The water in the system cools as it travels from one heat

there is less pipework emitter to the next, which has the effect of increasing the

KEY TERM involved in the installation heat emitter sizes the further from the boiler they are

when compared to other The system tends to circulate within the main pipework ring;

Boiler cycling: the constant heating systems circulation within the heat emitters can be induced only by

firing up and shutting a difference in the density of the water entering and leaving

down as the system water the system (gravity circulation)

cools slightly. When a Uncontrolled heating of the primary circuit leading to

heating system has reached overheating of the domestic secondary hot water

temperature, the boiler Constant boiler cycling even when the hot water and heating

shuts down on the boiler are up to temperature leads to wastage of fuel energy

thermostat. A few minutes

later the boiler will fire The system is not Building Regulations Document L

up again to top up the compliant and must be updated

temperature as the system The boilers fitted to this type of system are only about 78%

loses heat and, after a few efficient or less

seconds, shuts down again. Condensing-type boilers cannot be fitted to this type of

This wastes a lot of fuel installation because of the gravity circulation needed by the

energy. hot water storage cylinder

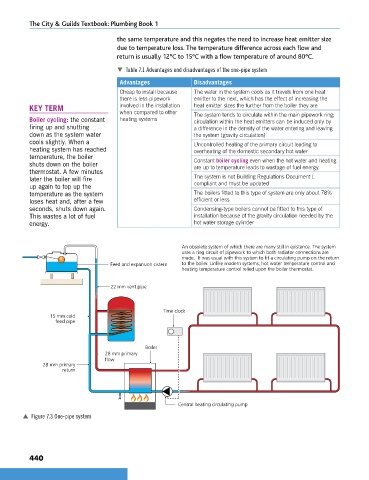

An obsolete system of which there are many still in existence. The system

uses a ring circuit of pipework to which both radiator connections are

made. It was usual with this system to fit a circulating pump on the return

Feed and expansion cistern to the boiler. Unlike modern systems, hot water temperature control and

heating temperature control relied upon the boiler thermostat.

22 mm vent pipe

Time clock

15 mm cold

feed pipe

Boiler

28 mm primary

flow

28 mm primary

return

Central heating circulating pump

p Figure 7.3 One-pipe system

440

9781510416482.indb 440 29/03/19 9:02 PM