Page 180 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 180

Fluid Flow 153

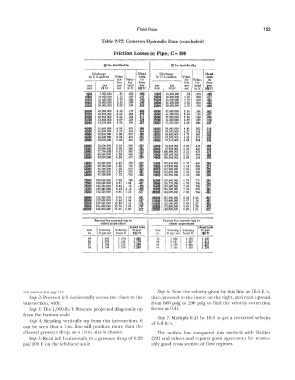

Table 2-22: Cameron Hydraulic Data (concluded)

Friction Losses in Pipe; C =-100

60 in. Inside d la 72 in. inside dla

Discharge Head Discharge Head

in US gallons Vc!oc- loss in US gallons Veloc- Ioss

ity Veloc- In ity Veloc- in

feet ity feet feet ity feet

I'<;' per per head per per per per head

1&i'lt

mm 24 hr sec -- -- min 24 hr sec -- --

in ft 100 ft

in ft

5000 7,200,000 .56 .005 .003 10000 14,400,000 .78 .009 .005

10000 IH00,000 1.12 .019 .011 20000 28,800,000 1.57 .038 .011

16000 21,600,000 1.70 .045 .024 25000 36,000,000 1. 97 .060 .02,

20000 28,800,000 2.26 .079 .042 30000 43,200,000 2.36 .086 .036

25000 36,000,000 2.83 .124 .062 35000 50,400,000 2. 76 .118 .048

30000 43,200,000 3.40 .179 -088 40000 57,600,000 3.16 .154 .062

32000 46,080,000 3.63 .205 -09' 45000 64,800,000 3.54 .194 .011

34000 48,960,000 3.86 .230 .111 5 � 000 72,000,000 3.94 .240 -094

36000 51,840,000 4.09 .259 -124 5 000 74,880,000 4.09 .259 .100

38000 54,720,000 4.32 .290 .137 54000 77,760,000 4.25 .280 ,107

40000 57,600,000 4.55 .320 -150 56000 80,540,000 4.41 .302 -114

42000 60,480,000 4. 78 .354 -164 58000 83,520,000 4.57 .324 .122

44000 63,360,000 5.00 .387 -180 60000 86,400,000 4.73 .347 .130

46000 66,240,000 5.22 .422 .196 62000 89,280,000 4.88 .370 -138

48000 69,020,000 5.45 .460 .212 64000 92,160,000 5.04 .384 .146

50000 72,000,000 5.68 .500 .229 66000 95,040,000 5.20 .420 .165

52000 74,880,000 5.90 .540 -246 68000 97,920,000 5.36 .447 -164

54000 77,760,000 6.12 .582 .263 70000 100,800,000 5.51 .473 .174

56000 80,540,000 6.35 .626 .281 72000 103,680.000 5.67 .499 -183

.672 .m

68000 83,520,000 6.68 74000 106,560,000 5.83 .528 .193

60000 86,400,000 6.81 . 720 -319 76000 109,440,000 5. 99 .558 .203

62000 89,280,000 7.03 . 768 .339 78000 11%,320,000 6.15 .588 -214

64000 92,160,000 7.25 .819 .360 80000 115,200,000 6.31 .620 .225

66000 95,040,000 7.49 .870 .381 82000 118,080,000 6.46 .650 .235

68000 97,920,000 7. 72 . 925 -403 84000 120,960,000 6. 62 .680 .245

70000 100,800,000 7.95 .980 -425 86000 123,840,000 6. 78 . 712 .256

72000 103,680,000 8.17 1.04 .447 88000 126,720,000 6. 93 . 746 -266

74000 106,560,000 8.40 .10 -470 9b000 129,600,000 7.09 . 780 .277

76000 109,440,000 8.62 1.15 .493 i5000 136,800,000 7. 49 .870 -30f

78000 112,320,000 8.86 1.22 .517 1 0000 144,000,000 7. 88 .965 .33

80000 115,200,000 9.06 1.28 .541 105000 151,200,000 8.28 1.06 .367

85000 122,400,000 9.64 i.44 .607 110000 15R,400,000 8. 67 1.16 -401

,0000 129,600,000 10.20 I. 61 -676 1!5000 165.600,000 9.05 1.27 .,m

95000 136,800,000 10. 78 1.80 .747 1 0000 112,roo,ooo 9. 45 1.38 .473

100000 144,000,000 11.36 2.00 .822 125000 i80, 00,000 I 9.85 1.51 .512

Factor for correcrtng to --Factor for correct ing to

other pipe size• other pipe sizes

Head 1088 Head Ioss

Dia Velocity Velocity ft per Dia Velocity Velocity ft per

ft per sec

iu

ft per sec head ft

100 ft

in

---- --- head ft 100 ft --- --- --- ----

59 1.034 1.070 1-085 70 1.058 1.119 1-147

58 1.070 1.145 1.179 68 1.121 1.257 1-3!8

57 1.108 1.228 1.284 66 1.190 1.416 1-5 7

56 1.148 1.318 I 1.399 64 l.266 1. 602 1-774

(text continued Jro11,. page 141) Step 6: Note the velocity given by this line as 16.5 ft/s,

Step 2: Proceed left horizontally across the chart to the then proceed to the insert on the right, and read upward

intersection, with: from 600 psig to 200 psig to find the velocity correction

Step 3: The 1,000-lb/h flowrate projected diagonally up factor as 0.41.

from the bottom scale.

Step 7: Multiply 0.41 by 16.5 to get a corrected velocity

Step 4: Reading vertically up from this intersection, it of 6.8 ft/s.

can be seen that a Lin. line will produce more than the

allowed pressure drop, so a 1!1,--in. size is chosen. The author has compared this method with Dukler

Step 5: Read left horizontally to a pressure drop of 0.28 [29] and others and reports good agreement for reason-

psi/100 ft on the left-hand scale. ably good cross section of flow regimes.