Page 630 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 630

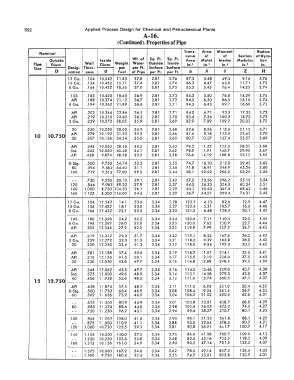

592 Applied Process Design for Chemical and Petrochemical Plants

A-16.

( Continued). Properties of Pipe

Radiu1

Nominal Trani- Area Moment Section of Gyra

vene

of

of

Ou hide ln1ide Wt. of Sq. Ft. Sq. Ft. Area Metal Inertia Modulu1 tion

Pipe Diam. Wall Diam. Weight Water Ouhide ln1ide in.• in. 1 in.• in. 3 in.

Size De1ig- Thick- per per Ft. Surface Surface z

D nation ne11 d Foot of Pipe per Ft. per Ft. a A I R

12 Ga. .104 10.542 11.83 37.8 2.81 2.76 87.3 3.48 49.3 9.16 3.76

10 Ga. .134 10.482 15.21 37.4 2.81 2.7 4 86.3 4.47 63.0 11.71 3.75

8 Ga. .164 10.422 18.56 37.0 2.81 2.73 85.3 5.45 76.4 14.22 3.74

lOS .165 10.420 18.65 36.9 2.81 2.73 85.3 5.50 76.8 14.29 3.74

API .188 10.374 21.12 36.7 2.81 2.72 I 84.5 6.20 86.5 16.10 3.74

6 Ga. .194 10.362 21.89 36.6 2.81 2.71 84.3 6.43 89.7 16.68 3.73

--

AP! .203 10.344 22.86 36.5 2.81 2.71 84.0 6.71 93.3 17.35 3.73

API .219 10.310 24.60 36.2 2.81 2.70 83.4 7.241 100.5 18.70 3.72

3 Ga. .239 10.272 28.05 35.9 2.81 2.69 82.9 7.89 109.2 20.32 3.72

8.26 I

20 .250 10.250 28.03 35.9 2.81 2.68 82.6 113.6 21.12 3.71

9.18

10 10.750 API .279 10.192 31.20 35.3 2.81 2.66 81.6 10.07 125.9 23.42 3.70

2.65

25.57

.307

137.4

80.7

10.136 34.24

3.69

35.0

30

2.81

API .344 10.062 38.26 34.5 2.81 2.63 79.5 11.25 152.3 28.33 3.68

Std. .365 10.020 40.48 34.1 2.81 2.62 78.9 11.91 160.7 29.90 3.67

API .438 9.874 48.28 33.2 2.81 2.58 76.6 14.19 188.8 35.13 3.65

- ---

X-Stg. .500 9.750 54.74 32.3 2.81 2.55 74.7 16.10 212.0 39.43 3.63

80 .594 9.562 64.40 31.1 2.81 2.50 71.8 18.91 244.9 45.56 3.60

100 .719 9.312 77.00 29.5 2.81 2.44 68. l 22.62 286.2 53.25 3.56

;:-:----i-·

- - .750 ----· 29.1 2.81 2.42 67.2 23.56 296.2 55.10 3.54

9.250 80.10

120 .844 9.062 89.20 27.9 2.81 2.37 64.5 26.23 324.3 60.34 3.51

140 1.000 8.750 104.20 26.1 2.81 2.29 I 60. l 30.63 367.8 I 68.43 3.46

160 1.125 8.500 116.00 24.6 2.81 2.22 I 56.7 34.01 399.4 ! 74.31 3.43

12 Go. .104 12.542 14.1 53.6 3.34 3.28 123.5 4.13 82.6 I 12.9 4.47

10 Ga. .134 12.482 18.1 53.0 3.34 3.27 122.4 5.31 105.7 16.6 4.46

8 Ga. .164 12.422 22.l 52.5 3.34 3.25 121.2 6.48 128.4 I 20.1 4.45

--- --- - 1 40.4-1

lOS .180 12.390 24.2 52.2 3.34 3.24 120.6 7.11 22.0 4.44

6 Go. .194 12.362 26.0 52.0 3.34 3.23 120.0 7.65 150.9 23.7 4.44

API .203 12.344 27.2 52.0 3.34 3.23 119.9 7.99 157.2 24.7 4.43

--- ·- ---

API .219 12.312 29.3 51.7 3.34 3.22 119.l 8.52 167.6 26.3 4.43

3 Ga. .239 12.272 32.0 51.3 3.34 3.21 118.3 9.39 183.8 28.8 4.42

20 .250 12.250 33.4 51.3 3.34 3.12 118.0 9.84 192.3 30.2 4.42

--- -----

API .281 12.188 37.4 50.6 3.34 3.19 116.7 11.01 214.1 33.6 4.41

API .312 12.126 41.5 50.1 3.34 3.17 115.5 12.19 236.0 37.0 4.40

" ...

30 .330 12.090 43.8 49.7 3.34 3.16 114.8 12.88 248.5 39.0 4.39

-- ·- ·-·-

-----

---

API .344 12.062 45.5 49.7 3.34 3.16 259.0 40.7 4.38

Std. .375 12.000 49.6 48.9 3.34 3.14 113.1 14.58 279.3 43.8 4.37

111.9

40 .406 11.938 53.6 48.5 3.34 3.13 '"D 15.74 300.3 47.1 4.37

12 12.750 ..

API .438 11.87 4 57.5 48.2 3.34 3.11 111.0 16.95 321.0 50.4 4.35

X-Stg. .500 11.750 65.4 46.9 3.34 3.08 108.4 19.24 361.5 56.7 4.33

60 .562 11.626 73.2 46.0 3.34 3.04 106.2 21.52 400.5 62.8 4.31

--- --- -------

- - .625 11.500 80.9 44.9 3.34 3.01 103.8 23.81 438.7 68.8 4.29

80 .688 11.374 88.6 44.0 3.34 2.98 101.6 26.03 475.2 74.6 4.27

- - .750 11.250 96.2 43.1 3.34 2.94 99.4 28.27 510.7 80. l 4.25

---- ---

. -- --·--

f--·

100 .844 11.062 108.0 41.6 3.34 2.90 96.1 31.53 561.8 88. l 4.22

. - .875 11.000 110.9 41.1 3.34 2.88 95.0 32.64 578.5 90.7 4.21

120 1.000 10.750 125.5 39.3 3.34 2.81 90.8 36.91 641.7 100.7 4.17

-- --

140 1.125 10.500 140.0 37.5 3.34 2.75 86.6 41.08 700.7 109.9 4.13

- - 1.250 10.250 153.6 35.8 3.34 2.68 82.5 45.16 755.5 118.5 4.09

160 1.312 10.126 161.0 34.9 3.34 2.65 80.5 47.14 781.3 122.6 4.07

·-

- - 1.375 10.000 167.2 34.0 --+------- 2.62 78.5 49.14 807.2 126.6 4.05

3.34

- - 1.500 9.750 180.4 32.4 3.34 2.55 I 74.7 53.01 853.8 133.9 4.01