Page 75 - Module DMV20173

P. 75

4.0 BULK DEFORMATION PROCESSES

7. This increases its resistance to deformation compared to the bulk. Thus the flash

plays a significant role in helping filling the die cavities.

3) Closed Die Forging

1. In closed-die-forging, no flash is formed and the workpiece is completely surrounded

by the dies.

2. Therefore, proper control of the volume of material is essential to obtain a forging of

desired dimensions.

3. Undersized blanks in close-die forging prevent the complete filling of the die, while

oversized blanks may cause premature die failure or jamming of the dies.

4.3.3 ADVANTAGES OF FORGING

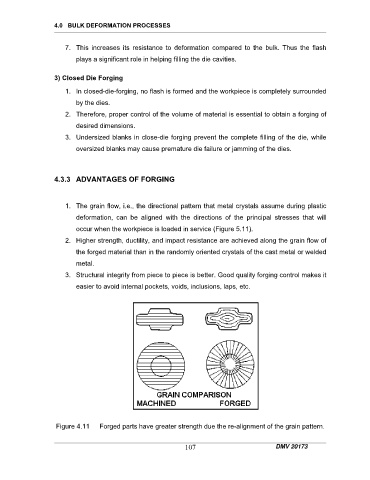

1. The grain flow, i.e., the directional pattern that metal crystals assume during plastic

deformation, can be aligned with the directions of the principal stresses that will

occur when the workpiece is loaded in service (Figure 5.11).

2. Higher strength, ductility, and impact resistance are achieved along the grain flow of

the forged material than in the randomly oriented crystals of the cast metal or welded

metal.

3. Structural integrity from piece to piece is better. Good quality forging control makes it

easier to avoid internal pockets, voids, inclusions, laps, etc.

Figure 4.11 Forged parts have greater strength due the re-alignment of the grain pattern.

BPLK 107 DMV 20173