Page 61 - Antelco Metric Catalogue 310320_FINAL.cdr

P. 61

Micro Irrigation: Facts to Consider

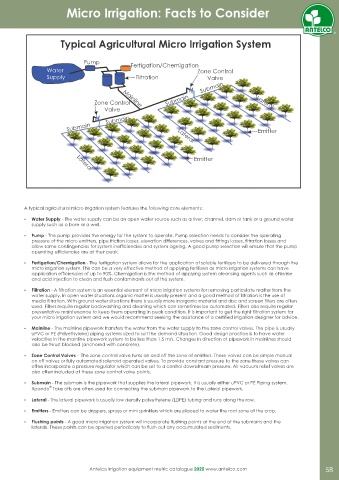

Typical Agricultural Micro Irrigation System

Pump

Fertigation/Chemigation

Water Zone Control

Supply Filtration Valve

Submain

Submain

Zone Control Lateral

Mainline

Valve

Submain

Submain Lateral Emitter

Emitter

Lateral

A typical agricultural micro irrigation system features the following core elements:

Ÿ Water Supply - The water supply can be an open water source such as a river, channel, dam or tank or a ground water

supply such as a bore or a well.

Ÿ Pump - The pump provides the energy for the system to operate. Pump selection needs to consider the operating

pressure of the micro emitters, pipe friction losses, elevation differences, valves and ttings losses, ltration losses and

allow some contingencies for system inefciencies and system ageing. A good pump selection will ensure that the pump

operating efciencies are at their peak.

Ÿ Fertigation/Chemigation - The fertigation system allows for the application of soluble fertilizers to be delivered through the

micro irrigation system. This can be a very effective method of applying fertilizers as micro irrigation systems can have

application efciencies of up to 90%. Chemigation is the method of applying system cleansing agents such as chlorine

and acid injection to clean and ush contaminants out of the system.

Ÿ Filtration - A ltration system is an essential element of micro irrigation systems for removing particulate matter from the

water supply. In open water situations organic matter is usually present and a good method of ltration is the use of

media ltration. With ground water situations there is usually more inorganic material and disc and screen lters are often

used. Filters require regular backwashing and cleaning which can sometimes be automated. Filters also require regular

preventative maintenance to keep them operating in peak condition. It is important to get the right ltration system for

your micro irrigation system and we would recommend seeking the assistance of a certied irrigation designer for advice.

Ÿ Mainline - The mainline pipework transfers the water from the water supply to the zone control valves. The pipe is usually

uPVC or PE (Polyethylene) piping systems sized to suit the demand situation. Good design practice is to have water

velocities in the mainline pipework system to be less than 1.5 m/s. Changes in direction of pipework in mainlines should

also be thrust blocked (anchored with concrete).

Ÿ Zone Control Valves - The zone control valve turns on and off the zone of emitters. These valves can be simple manual

on off valves or fully automated solenoid operated valves. To provide constant pressure to the zone these valves can

often incorporate a pressure regulator which can be set to a control downstream pressure. Air vacuum relief valves are

also often included at these zone control valve points.

Ÿ Submain - The submain is the pipework that supplies the lateral pipework. It is usually either uPVC or PE Piping system.

®

Xpando Take offs are often used for connecting the submain pipework to the Lateral pipework.

Ÿ Lateral - The lateral pipework is usually low density polyethylene (LDPE) tubing and runs along the row.

Ÿ Emitters - Emitters can be drippers, sprays or mini sprinklers which are placed to water the root zone of the crop.

Ÿ Flushing points - A good micro irrigation system will incorporate ushing points at the end of the submains and the

laterals. These points can be opened periodically to ush out any accumulated sediments.

Antelco irrigation equipment metric catalogue 2020 www.antelco.com 58