Page 28 - Waterjet

P. 28

2030

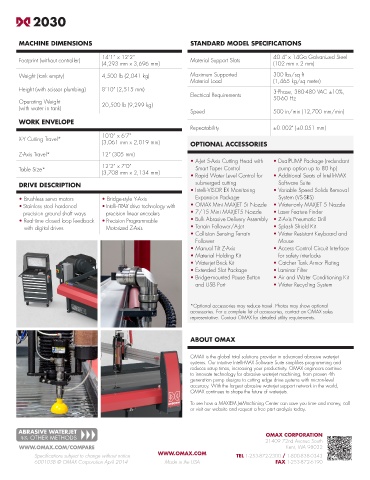

MACHINE DIMENSIONS STANDARD MODEL SPECIFICATIONS

14’1” x 12’2” 40 4" x 14Ga Galvanized Steel

Footprint (without controller) Material Support Slats

(4,293 mm x 3,696 mm) (102 mm x 2 mm)

Weight (tank empty) 4,500 lb (2,041 kg) Maximum Supported 300 lbs/sq ft

Material Load (1,465 kg/sq meter)

Height (with scissor plumbing) 8’10” (2,515 mm) 3-Phase, 380-480 VAC ±10%,

Electrical Requirements

Operating Weight 50-60 Hz

(with water in tank) 20,500 lb (9,299 kg)

Speed 500 in/min (12,700 mm/min)

WORK ENVELOPE

Repeatability ±0.002" (±0.051 mm)

10’0” x 6’7”

X-Y Cutting Travel*

(3,061 mm x 2,019 mm) OPTIONAL ACCESSORIES

Z-Axis Travel* 12” (305 mm)

• A-Jet 5-Axis Cutting Head with • DualPUMP Package (redundant

12’2” x 7’0”

Table Size* Smart Taper Control pump option up to 80 hp)

(3,708 mm x 2,134 mm)

• Rapid Water Level Control for • Additional Seats of Intelli-MAX

DRIVE DESCRIPTION submerged cutting Software Suite

• Intelli-VISOR EX Monitoring • Variable Speed Solids Removal

• Brushless servo motors • Bridge-style Y-Axis Expansion Package System (VS-SRS)

• Stainless steel hardened • Intelli-TRAX drive technology with • OMAX Mini MAXJET 5i Nozzle • Water-only MAXJET 5 Nozzle

precision ground shaft ways precision linear encoders • 7/15 Mini MAXJET5 Nozzle • Laser Feature Finder

• Real-time closed loop feedback • Precision Programmable • Bulk Abrasive Delivery Assembly • Z-Axis Pneumatic Drill

with digital drives Motorized Z-Axis • Terrain Follower/A-Jet • Splash Shield Kit

• Collision Sensing Terrain • Water Resistant Keyboard and

Follower Mouse

• Manual Tilt Z-Axis • Access Control Circuit Interface

• Material Holding Kit for safety interlocks

• Waterjet Brick Kit • Catcher Tank Armor Plating

• Extended Slat Package • Laminar Filter

• Bridge-mounted Pause Button • Air and Water Conditioning Kit

and USB Port • Water Recycling System

*Optional accessories may reduce travel. Photos may show optional

accessories. For a complete list of accessories, contact an OMAX sales

representative. Contact OMAX for detailed utility requirements.

ABOUT OMAX

OMAX is the global total solutions provider in advanced abrasive waterjet

systems. Our intuitive Intelli-MAX Software Suite simplifies programming and

reduces setup times, increasing your productivity. OMAX engineers continue

to innovate technology for abrasive waterjet machining, from proven 4th

generation pump designs to cutting edge drive systems with micron-level

accuracy. With the largest abrasive waterjet support network in the world,

OMAX continues to shape the future of waterjets.

To see how a MAXIEM JetMachining Center can save you time and money, call

or visit our website and request a free part analysis today.

ABRASIVE WATERJET

vs. OTHER METHODS OMAX CORPORATION

21409 72nd Avenue South

WWW.OMAX.COM/COMPARE Kent, WA 98032

Specifications subject to change without notice. WWW.OMAX.COM TEL 1-253-872-2300 / 1-800-838-0343

600103B © OMAX Corporation April 2014 Made in the USA FAX 1-253-872-6190