Page 163 - 2018 Master Catalog

P. 163

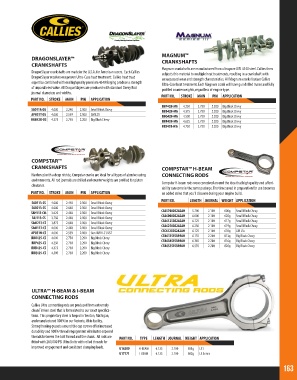

MAGNUM™

DRAGONSLAYER™ CRANKSHAFTS

CRANKSHAFTS

DragonSlayer crankshafts are made in the U.S.A. for American racers. Each Callies Magnum crankshafts are manufactured from ultra pure AISI 4340 steel. Callies then

subjects this material to multiple heat treatments, resulting in a crankshaft with

DragonSlayer receives our proven Ultra-Case heat treatment. Callies heat treat unsurpassed wear and strength characteristics. All Magnum cranks feature Callies

expertise combined with our high purity premium 4340 forging produce a strength Ultra-Case heat treatment. Each Magnum crank will have gun drilled mains and fully

of unparalleled value. All DragonSlayers are produced with standard Chevy Rod profiled counterweights, regardless of engine type.

journal diameters and widths. PART NO. STROKE MAIN PIN APPLICATION

PART NO. STROKE MAIN PIN APPLICATION

BBP42B-MG 4.250 2.750 2.200 Big Block Chevy

SAO11A-DS 4.000 2.248 2.100 Small Block Chevy BBB42B-MG 4.375 2.750 2.200 Big Block Chevy

APO31T-DS 4.000 2.559 2.100 GM LS1 BBQ42B-MG 4.500 2.750 2.200 Big Block Chevy

BBB42B-DS 4.375 2.750 2.200 Big Block Chevy BBR42B-MG 4.625 2.750 2.200 Big Block Chevy

BBS42B-MG 4.750 2.750 2.200 Big Block Chevy

COMPSTAR™

CRANKSHAFTS COMPSTAR™ H-BEAM

Hardened with a deep nitride, Compstar cranks are ideal for all types of abusive racing CONNECTING RODS

environments. All rod journals are drilled and counterweights are profiled for piston

clearance. Compstar H-beam rods were conceived around the idea that high quality and afford-

ability can come in the same package. The time saved in preparation for use becomes

PART NO. STROKE MAIN PIN APPLICATION an added value that you’ll discover during your engine build.

PART NO. LENGTH JOURNAL WEIGHT APPLICATION

SAO113-CS 4.000 2.448 2.100 Small Block Chevy

SAO213-CS 4.000 2.648 2.100 Small Block Chevy

SAH113-CM 3.625 2.448 2.100 Small Block Chevy CSA5700DS2A2AH 5.700 2.100 606g Small Block Chevy

SAJ113-CS 3.750 2.448 2.100 Small Block Chevy CSA6000DS2A2AH 6.000 2.100 620g Small Block Chevy

SAM213-CS 3.875 2.648 2.100 Small Block Chevy CSA6125DS2A2AH 6.125 2.100 617g Small Block Chevy

SAM113-CS 4.000 2.448 2.100 Small Block Chevy CSA6250DS2A2AH 6.250 2.100 619g Small Block Chevy

APO31N-CS 4.000 2.559 2.100 Gen III/IV LS1/LS7 CSC6125DS2A2AH 6.125 2.100 618g GM LSx

BBO425-CS 4.000 2.750 2.200 Big Block Chevy CSB6135ES3B9AH 6.135 2.200 813g Big Block Chevy

BBP425-CS 4.250 2.750 2.200 Big Block Chevy CSB6385ES3B9AH 6.385 2.200 816g Big Block Chevy

BBB425-CS 4.375 2.750 2.200 Big Block Chevy CSB6535ES3B9AH 6.535 2.200 820g Big Block Chevy

BBQ425-CS 4.500 2.750 2.200 Big Block Chevy

ULTRA™ H-BEAM & I-BEAM

CONNECTING RODS

Callies Ultra connecting rods are produced from extremely

clean Timken steel that is formulated to our exact specifica-

tions. This proprietary steel is forged in Trenton, Michigan,

and manufactured 100% in our Fostoria, Ohio facility.

Strengthening gussets around the cap screws offer increased

durability and 100% thread engagement eliminates exposed

threads between the bolt thread and the shank. All rods are PART NO. TYPE LENGTH JOURNAL WEIGHT APPLICATION

fitted with 260,000 PSI Ultra Bolts with rolled threads for

improved engagement and consistent clamping loads. U16300 H-BEAM 6.125 2.100 651g LS1

U17171 I-BEAM 6.125 2.100 662g LS Series

163