Page 264 - 2018 Master Catalog

P. 264

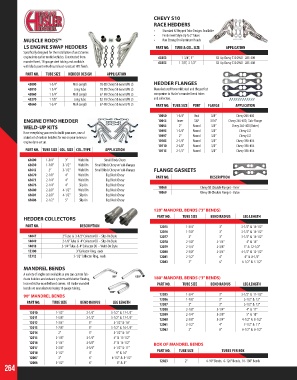

CHEVY S10

RACE HEDDERS

• Standard & Stepped Tube Designs Available

• Fenderwell Style Up To 2” Tubes

MUSCLE RODS™ • Run Strong On Aluminum Heads

LS ENGINE SWAP HEDDERS PART NO. TUBE & COL. SIZE APPLICATION

Specifically designed for the installation of an LS Series

engine into earlier model vehicles. Constructed from 65853 1-3/4”, 3” 82-Up Chevy S10 2WD - 283-400

mandrel-bent, 18-gauge steel tubing and available 65855 1-7/8”, 3-1/2” 82-Up Chevy S10 2WD - 283-400

with black paint or Hedman’s heat-resistant HTC finish.

PART NO. TUBE SIZE HEDDER DESIGN APPLICATION

45000 1-3/4” Mid-Length 78-88 Chevy SB Gen III/IV LS HEDDER FLANGES

45010 1-3/4” Long Tube 78-88 Chevy SB Gen III/IV LS Manufactured from mild steel and the perfect

45060 1-3/4” Mid-Length 67-69 Chevy SB Gen III/IV LS companion to Husler’s mandrel bend tubes

45270 1-7/8” Long Tube 82-93 Chevy SB Gen III/IV LS and collectors.

45660 1-3/4” Mid-Length 67-98 Chevy SB Gen III/IV LS PART NO. TUBE SIZE PORT FLANGE APPLICATION

10050 1-3/4” Oval 3/8” Chevy 265-400

ENGINE DYNO HEDDER 10045 Inner SAP 5/16” Chevy 265-400, Sub-Flange

WELD-UP KITS 10055 2” Round 3/8” Chevy 265-400 (Outer)

Have everything you need to build your own, one of 10495 1-3/4” Round 3/8” Chevy LS1

a kind set of custom hedders for use on your in-house 10497 2” Round 3/8” Chevy LS1

engine dyno set up. 10105 2-1/4” Round 3/8” Chevy 396-454

10110 2-3/8” Round 3/8” Chevy 396-454

PART NO. TUBE SIZE COL. SIZE COL. TYPE APPLICATION 10115 2-1/2” Round 3/8” Chevy 396-454

65600 1-3/4” 3” Weld On Small Block Chevy

65630 1-7/8” 3-1/2” Weld On Small Block Chevy w/ sub-flanges

65642 2” 3-1/2” Weld On Small Block Chevy w/ sub-flanges FLANGE GASKETS

65670 2-1/8” 4” Weld On Big Block Chevy PART NO. DESCRIPTION

65675 2-1/4” 4” Weld On Big Block Chevy

65676 2-1/4” 4” Slip On Big Block Chevy 18068 Chevy SB (Double Flange) - Inner

65680 2-3/8” 4-1/2” Weld On Big Block Chevy 18069 Chevy SB (Double Flange) - Outer

65681 2-3/8” 4-1/2” Slip On Big Block Chevy

65686 2-1/2” 5” Slip On Big Block Chevy

120° MANDREL BENDS (“J” BENDS)

HEDDER COLLECTORS PART NO. TUBE SIZE BEND RADIUS LEG LENGTH

PART NO. DESCRIPTION 12075 1-3/4” 3” 3-1/2” & 14-1/2”

12076 1-7/8” 3” 3-1/2” & 14-1/2”

14047 2” Tube & 3-1/2” Collector OD - Slip-On Style 12077 2” 3” 3-1/2” & 14-1/2”

14049 2-1/8” Tube & 4” Collector OD - Slip-On Style 12078 2-1/8” 3-1/4” 4” & 14”

14018 2-1/4” Tube & 4” Collector OD - Weld-On Style 12079 2-1/4” 3-3/8” 5” & 12-1/2”

15300 3” Collector Ring, each 12080 2-3/8” 3-3/4” 4-1/2” & 12-1/2”

15312 3-1/2” Collector Ring, each 12081 2-1/2” 4” 6” & 8-1/2”

12083 3” 6” 6-1/2” & 5-1/2”

MANDREL BENDS

A variety of angles are available so you can custom fab-

ricate hedders and exhaust systems with better flowing, 180° MANDREL BENDS (“J” BENDS)

less restrictive mandrel bent curves. All Husler mandrel PART NO. TUBE SIZE BEND RADIUS LEG LENGTH

bends are manufactured using 18 gauge tubing.

90° MANDREL BENDS 12055 1-3/4” 3” 3-1/2” & 11-1/2”

PART NO. TUBE SIZE BEND RADIUS LEG LENGTH 12056 1-7/8” 3” 3-1/2” & 12”

12057

3”

3-1/2” & 12”

2”

12058 2-1/8” 3-1/4” 4” & 11”

12010 1-1/2” 2-1/4” 3-1/2” & 17-1/2” 12059 2-1/4” 3-3/8” 5” & 10”

12011 1-5/8” 2-1/2” 3-1/2” & 17-1/2” 12060 2-3/8” 3-3/4” 4-1/2” & 8-1/2”

12012 1-3/4” 3” 3-1/2” & 16” 12061 2-1/2” 4” 7-1/2” & 11”

12013 1-7/8” 3” 3-1/2” & 16-1/2” 12063 3” 6” 6-1/2” & 6-1/2”

12014 2” 3” 3-1/2” & 16”

12015 2-1/8” 3-1/4” 4” & 15-1/2”

12016 2-1/4” 3-3/8” 5” & 14-1/2” BOX OF MANDREL BENDS

12017 2-3/8” 3-3/4” 4-1/2” & 11” TUBE SIZE TUBES PER BOX

12018 2-1/2” 4” 9” & 16” PART NO.

12007 3” 6” 6-1/2” & 8-1/2”

12006 3-1/2” 6” 8” & 8” 12023 2” 4- 90° Bends, 4- 120° Bends, 10- 180° Bends

264