Page 45 - MGPI_Case_Study

P. 45

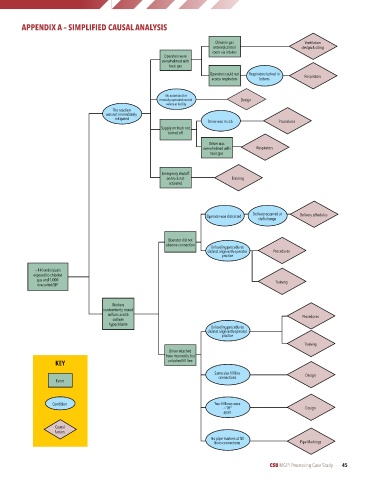

APPENDIX A – SIMPLIFIED CAUSAL ANALYSIS

Chlorine gas Ventilation

entered control design & siting

room via intakes

Operators were

overwhelmed with

toxic gas

Operators could not Respirators locked in Respirators

access respirators lockers

No automated or

remotely operated control Design

valves at facility

The reaction

was not immediately

mitigated

Driver was in cab Procedures

Supply on truck not

turned off

Driver was

overwhelmed with Respirators

toxic gas

Emergency shutoff

on truck not Training

activated

Delivery occurred at

Operator was distracted Delivery schedules

shift change

Operator did not

observe connection

Unloading procedures

did not align with operator Procedures

practice

~140 individuals

exposed to chlorine

gas and 1,000 Training

evacuated/SIP

Workers

inadvertently mixed

sulfuric acid & Procedures

sodium

hypochlorite

Unloading procedures

did not align with operator

practice

Training

Driver attached

hose incorrectly but

unlocked fill line

KEY

Same size fill line

connections Design

Event

Condition Two fill lines were

~18" Design

apart

Causal

Factors

No pipe markers at fill

lines connections Pipe Markings

CSB MGPI Processing Case Study 45